Fiber Optic Center will be at Anga Com - Schedule your meeting with a member of the FOC team now

fiber optic installation

Explore the Fiber Optic Center Technical Content Library for

Answers to your most pressing installation questions.

Search a comprehensive database of resources, including technical papers, best practices, tips, FAQs, and more.

DISTRIBUTING INSTALLATION PRODUCTS FROM TRUSTED MANUFACTURERS

The Fiber Optic Center Difference

Onsite technical support and consultation for every product offered

... at no additional charge

0+

Articles, Content

0+

Years of Experience

0+

Technical Experts

0+

Global Offices

Featured Products

Fiber Optic Center features products to highlight attributes that deliver value to end-users and differentiate a product in the market. Selection is based on but not exclusive to design, quality, functionality, and experience.

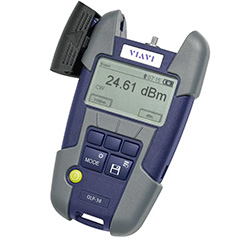

VIAVI SMARTPOCKET OLP-38 POWER METER (+26 DBM)

Viavi SmartPocket Optical Power Meters (OLP-34, OLP-35, and OLP-38) offer an excellent price/performance ratio in a rugged and pocket-sized housing for straightforward use in the field...

Find out more

AFL CSM 1-2 POWER METER (850, 1300, 1310 AND 1550NM)

Combining the CSM 1-2 optical power meter and a CSS light source will lead to a cost-effective test kit designed for performing insertion loss measurements on multimode or single mode fiber optic...

Find out moreBrowse our complete product line for cable assembly production, services, additional fiber applications and specialty applications, by clicking links below.

Cable Assembly Production

Shop allAdditional Fiber Applications & Specialty Applications