Published: July 1, 2017

QUESTION: How does an electrostatic charge get onto a fiber optic ferrule and how does that create contamination issues?

ANSWER:

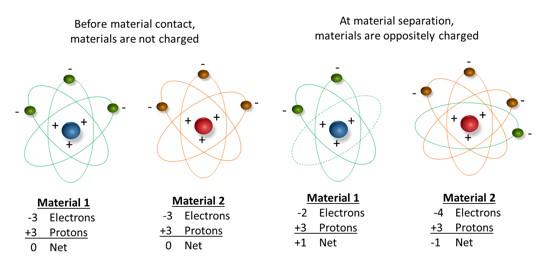

The electrostatic charge that gets onto a ferrule is usually caused by contract friction also known as triboelectric charging. Triboelectric charging happens when the surface electronics of two different materials move from the surface when during contact. Many people have experienced triboelectric charging when they walk across a carpet during the cold, dry winter months and touch a metal door knob. The static charge was caused by the contact friction of your shoes and the carpet.

If one material surface loses some electronics in the contact process, it will become a positively charged surface. The second material that picked up the electronics will have a negative charge because of the extra electrons.

Contact friction happens all the time with fiber optic connectors. There is contact friction when a connector is inserted into an adapter. There is contact friction when the connector surface is being wiped during the cleaning process. Connector end faces near equipment cooling fans are vulnerable. The dust in the air makes contact with the friction of the fan blades. The dust becomes electrostatically charged and bonds with oppositely charged surfaces.

The most common contamination problem with fiber connectors are dust particulates. When a ferrule end face becomes electrostatically charged, it is going to attract oppositely charged dust particles so the surface can return to an electrically neutral state.

ADDITIONAL CONTENT & RESOURCES:

- Category Resource: FOC Cleaning Page

- Find More Information in this Blog: The art of cleaning: Follow these specific cleaning techniques during fiber optic cable assembly manufacturing and installation

Have a technical question for Fiber Optic Center?

Please email your question to AskFOC@focenter.com and we will respond ASAP.

In addition to replying, we will post your question and our answer here on focenter.com. Everyone remains anonymous when we post so feel comfortable asking. You can also search your question and others in our content search.

Follow:@FiberOpticCntr