QUESTION: When should I use stick cleaner and what are some limitations to using these types of cleaners?

ANSWER:

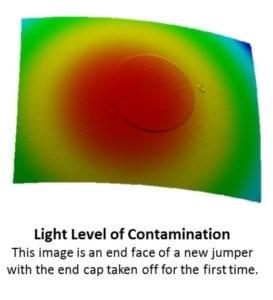

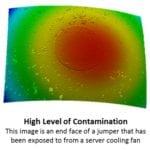

Mechanical click cleaners are good for cleaning light to medium levels of end face contamination when you have many connector pairs that need to be cleaned. The basic mechanical action of the click cleaners is to have the cleaning tip rotate 180° which the cleaning strand flows across the tip. The effect is a sweep and lifting motion for wiping away contamination off the ferrule end face. Most mechanical cleaners have a spring loaded cleaning tip for controlling the contact force. If the ferrule end face has lot of residues or has a high to severe level of contamination, the mechanical click cleaners may not be able to wipe away enough of the contamination from the ferrule end face. Higher levels of end face contamination are usually encountered in outside plant networks and legacy networks that have not been properly maintained over many years.

Most mechanical click cleaners have barrels and end caps that are designed to ensure the cleaner’s cleaning tip is wiping away end face contamination from the contact zone on the ferrule. The self-alignment feature eliminates the need for the good technique by the operator which means consistency with the mechanical click cleaner’s cleaning performance. Mechanical click cleaners usually offer a lower cost per clean when compared to other cleaning options like cassette based cleaners and stick cleaners. The way to determine cost per clean is to take the price of the cleaner and divide it by the number of uses.

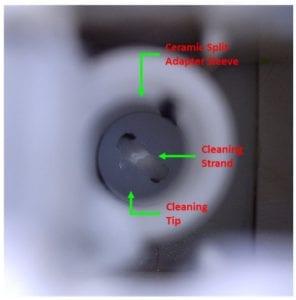

There are some limitation with mechanical click cleaners. The cleaning region of mechanical click cleaners will never be able to completely clean a ferrule end face. The cleaning tip has to be able to fit inside and rotate unobstructed through the adapter sleeve.

If your application is experiencing issues with particle migration, the better option may be to use a stick cleaner.

The mechanical click cleaners will not be able to remove any dust contamination on the adapter sleeve.

ADDITIONAL CONTENT & RESOURCES:

- Category Resource: FOC Cleaning Page

- Find More Information in this Blog: The art of cleaning: Follow these specific cleaning techniques during fiber optic cable assembly manufacturing and installation

Have a technical question for Fiber Optic Center?

Please email your question to AskFOC@focenter.com and we will respond ASAP.

In addition to replying, we will post your question and our answer here on focenter.com. Everyone remains anonymous when we post so feel comfortable asking. You can also search your question and others in our content search.