Part 1: Introduction to Fiber Optic Cable Assembly Manufacturing

Introduction

Is your company entering the fiber optic cable assembly market? Here at Fiber Optic Center, we believe it’s important to introduce engineers and technicians to various aspects of the production process to manufacture high-performance, world-class fiber optic cable assemblies. Ideally, your finished fiber optic cable assembly will meet all relevant international standards for quality, performance, and long-term reliability.

First, though, you and your team will need to learn the elementary principles of fiber optics, light, and transmission; connector manufacturing procedures; fundamentals of connector polishing and applicable industry standards; as well as diagnostic and troubleshooting techniques.

In this ongoing series of online articles – “Introduction to Fiber Optic Cable Assembly Manufacturing” – we’ll introduce you to a wide variety of topics to accelerate your education. This inaugural article presents an overview of fiber optic cable construction and optic fiber geometry.

Components of the fiber optic patch cord (cable assembly)

The majority of our customers manufacture fiber optic cable assemblies, which are widely known as patch cords. Patch cords can be simplex or duplex. A simplex cable consists of a single strand of optic fiber. A duplex cable is composed of two insulated single-conductor optic fibers. (We encourage you to review the Fiber Optic Center Glossary to familiarize yourself with the wide range of industry terminology.)

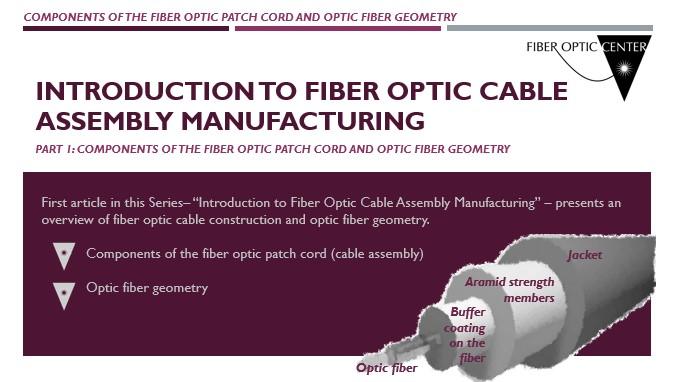

Here are the four major components of the fiber optic patch cord:

- Jacket – The jacket is the external covering of the fiber optic cable. While it offers protection, its primary purpose is not to provide strength. Essentially, the jacket holds all components together: the aramid strength members and buffered fiber, which encompass the optic fiber.

- Aramid strength members – Aramid yarns are strong, heat-resistant fibers. In the fiber optic cable assembly, the aramid strength members provide tensile strength from the connector and throughout the cable. For example, during the manufacturing process, as you pull the cable onto the connector, the aramid strength members help to assure the cable and the glass optic fiber won’t break. (Note that aramid strength members are often referred to as Kevlar®, which is a trademarked name for a particular brand of aramid yarn.)

- Buffer coating on the fiber – The glass optic fiber is manufactured with a protective (buffer) coating against damage. Depending on the patch cord’s application, the buffer coating can be a variety of different materials that will offer, for example, resistance to high temperatures or fire resistance. The buffer also protects the acrylate-coated fiber as it is extruded into the jacket as well as acting as a “seal,” if you will, of that acrylate-coated fiber before splicing or connectorization.

- Optic fiber – Manufactured from glass or plastic, the optic fiber is an optical waveguide comprised of a light-carrying core and cladding, which traps light in the core. Fiber optic communication systems use either single-mode or multimode types.

Optic fiber geometry

It’s helpful to understand that manufacturers of optic fiber pay close attention to certain geometric parameters. It’s extremely important for them to maintain the stated tolerances – the exact physical dimensions – so the optic fiber will provide repeatable results.

Optic fiber has the following geometric parameters:

- Core-to-clad concentricity – In fiber optics, the core is the transparent section of the glass (or plastic) fiber. The core has a high refractive index through which the light travels by internal reflections. Core-to-clad concentricity is a measure of the relationship between the geometric center of the core of an optical fiber and the geometric center of the cladding. In other words, core-to-clad concentricity measures how centered the core is in the optic fiber.

- Clad diameter – Fiber optic cladding is a layer of glass (or other material) surrounding the core of the optic fiber. The cladding has a refractive index that is slightly lower than the core and forms a conduit that carries light through the fiber.

- Mode field diameter – This is the diameter of optical energy in a single-mode fiber. Because the mode field diameter (MFD) is greater than the core diameter, MFD replaces core diameter as a practical geometric parameter.

These geometric parameters are expressed in microns. Plus, the individual specifications of various optic fibers are propriety to each manufacturer of optic fiber. Keep in mind, there are many different styles of optic fiber and physical sizes, which impact the geometric parameters.

Again, we encourage you to review the Fiber Optic Center Glossary to familiarize yourself with industry terminology. And we encourage you to take advantage of the following resources to continue your education:

- View Fiber and Cable Technical Solution Content

- View the Glossary, Acronyms, Military Specifications for Connectors

- Q&A Resource: email technical questions to AskFOC@focenter.com

EDITOR’S NOTE: This is the first article in an ongoing series, “Introduction to Fiber Optic Cable Assembly Manufacturing”:

- Part 1: Components of the Fiber Optic Patch Cord and Optic Fiber Geometry

- Part 2: Key Components of Fiber Optic Connectors and Key Specifications of Connectors

- Part 3: The 101 on Fiber Optic Connector Types

- Part 4: Establishing Internal Industry Product Standards for Fiber Optic Assemblies