QUESTION: Where does dust based end face contamination come from?

ANSWER:

There are two basic sources of dust based contamination.

-

Wear Debris

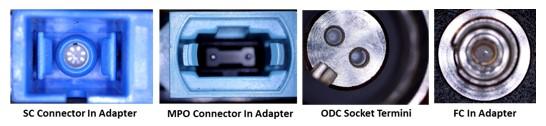

The most common source is wear debris caused by the contact friction of inserting a connector into the adapter. Connectors like the SC and MPO have sliding housing that are held in place by latches in the adapter. Other connector systems like the ST, FC, and many of the hardened connector systems have metal housings that are threaded and use orientation keys that generate wear debris. Other sources of wear debris are the protective end caps. Removing the end caps from a connector that was perfectly clean during the last inspection at factory will cause the end face to become contaminated when the end cap is removed by the installer.

2. Environmental Dust

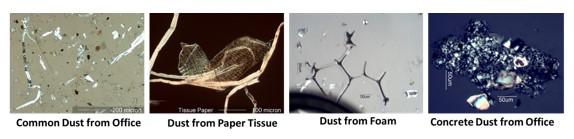

The other common contributors for dust based contamination is our environment. The common sources of dust in the air that contribute to dust based contamination include:

-

Dead skin, hair, and clothing lint

-

Foam based swabs and paper based wipes

-

Zinc whiskers from electroplated surfaces

-

Cardboard packaging

-

Plant pollen and molds

-

Aerial blown dirt and sands

-

Concrete and carpet dust

-

Electricity generation & vehicle emissions

ADDITIONAL CONTENT & RESOURCES:

- Category Resource: FOC Cleaning Page

- Find More Information in this Blog: The art of cleaning: Follow these specific cleaning techniques during fiber optic cable assembly manufacturing and installation

Have a technical question for Fiber Optic Center?

Please email your question to AskFOC@focenter.com and we will respond ASAP.

In addition to replying, we will post your question and our answer here on focenter.com. Everyone remains anonymous when we post so feel comfortable asking. You can also search your question and others in our content search.

This article is an original publication of Fiber Optic Center, Inc. It is shared publicly for educational and reference purposes to support learning and professional development within the fiber optics industry.

You are welcome to read, cite, or reference this material for non-commercial and educational purposes, as long as full credit is given to Fiber Optic Center, Inc. and the author.

Reuse, reproduction, or adaptation of this content — including rewriting, republishing, or incorporating it into new materials (such as websites, blogs, marketing text, technical guides, or AI-generated content) — is not permitted without prior written consent from Fiber Optic Center, Inc.

This material is protected by copyright law upon publication, even if not formally registered.

Use of this content for AI training, automated data extraction, or derivative content generation is prohibited.

Fiber Optic Center monitors and enforces the integrity of its intellectual property through digital identifiers and content tracking.

For more details, please refer to the Fiber Optic Center Content Use and Copyright policy.