Since 2018, FOC has provided more than 10 articles on making fiber and preforms. One series of seven articles, launched in January 2018 and written by Larry Donalds, focuses on MCVD technology and issues in making preforms. The second series, started in July 2020 and written by Rick Tumminelli, includes three articles on rare-earth doped fibers. The link to the complete library can be found at the end of this article. In the article below, the two FOC fiber-making experts offer more background on the wide range of specialty fibers, how they differ from standard communications fibers, and special issues encountered in the preform and draw processes.

Communication systems often incorporate specialty fibers

Fiber optics technology has revolutionized the communications industry. After several decades of deployment, fiber networks carry phone, TV, and Internet services, either part of the way to the end-users, or in many cases, all the way to the home. These services are pervasive and well-used. In 2018 for example, US adults averaged 8.5 hours per day of “screen time” – using a smartphone, TV, tablet, or PC. With the Covid-19 pandemic, average adult usage jumped more than 50% to 13.5 hours per day of screen time in 20201.

The jump in usage has included more video-conferencing and other video services, which require more network capacity than web pages and audio communications. The fiber networks generally handled the higher loads with minimal disruption. In some cases, network operators increased network capacity by

“lighting up” more fibers, by adding wavelength channels, or by increasing bit rates. This illustrates the vast capacity and flexibility of today’s fiber networks.

Since the 1980s, there have been significant advances in fiber systems’ capacity—characterized in terms of bandwidth and distance. In the early years, fiber system bandwidth was greater than that of copper but nowhere near what is required today. Distance performance was limited by optical loss in the fiber, so that repeater stations were needed every 100 km or so to receive the optical signal, clean it up electronically (reshape and retime) and then retransmit it.

All that changed with development and use of a specialty fiber – one doped with erbium (Er), a rare-earth element – to make optical amplifiers. The Er dopant provides optical gain over a wavelength band near the communication fiber’s 1.55-µm low-loss “window.” An Er-doped fiber amplifier (EDFA) boosts the transmission signal optically, eliminating the need for electronic “reshape-retime-and-regenerate” repeaters. Further, one EDFA can amplify multiple wavelength channels in the same fiber without crosstalk, allowing huge increases in fiber system bandwidth2. In this case, the specialty fiber complements the use of the communications fiber to substantially improve bandwidth and distance performance.

How specialty fibers differ from communication fibers

“Specialty fibers” can be defined as those fibers that do NOT comply with single-mode and multimode communication fiber standards. For single-mode, the International Telecommunications Union (ITU) standards are widely adopted3. For multimode, the US-based Telecommunications Industry Association’s Fiber Optics Tech Consortium (TIA FOTC) standards are widely adopted. These MM fiber specifications also are standardized by the International Organization for Standardization’s International Electrotechnical Commission (ISO-IEC).4.

In both cases, “widely adopted” means that the fiber specifications are used by the fiber and cable manufacturers, as well as companies that make transmit-receive components, connectors, and other products that interface with the fibers. Further, these fiber standards are also referenced in standards for local area networks, telecom systems, and other infrastructure. The fiber standards specify geometric, physical, and optical properties.

Communication fibers are designed to transmit a modulated optical signal at specific wavelengths. The fiber design is optimized for low loss and modal properties that support distance and bandwidth requirements. Specialty fibers are optimized for applications other than signal transmission, such as amplifiers, sensors, lasers, filters, ring resonators, etc. To serve such varied applications, there are hundreds of different specialty fiber types, with many variations in glass composition, core and cladding structures, geometric properties, coatings, and specially tailored optical performance characteristics. Some main families of specialty fibers are characterized by:

- special dopants in the glass, especially in the core;

- structures that result in birefringence for polarization-maintaining fiber;

- multiple claddings;

- special index profiles to tailor launch characteristics, numerical aperture (NA), effective area, mode propagation, and other waveguide properties;

- various combinations of these features.

The table below gives examples of specialty fibers and some typical applications. In the table and the rest of this article, we are discussing silica-based fibers that can use chemical vapor deposition for at least part of the preform process. (There also are specialty fibers that are based on chalcogenides, fluorides, and other glass materials. These non-silica fibers use different fabrication processes and are not discussed here.). The table shows that many specialty fiber types are designed for sensing systems. Fiber-based sensors can measure a vast array of chemical, physical, environmental, and biological parameters. The breadth of sensing applications is a key reason why there are so many types of specialty fibers.

Communications Fibers

| Type | Application |

|---|---|

| Single-mode communications fiber | Telecom and CATV networks

|

| Single-mode communications fiber | Campus and premise networks |

| Single-mode communications fiber | Data center networks and internal connections |

| Single-mode communications fiber | Others

|

|

Multimode communications fiber |

Campus and premise networks with spans up to 2 km |

|

Multimode communications fiber |

Data center networks and internal connections |

|

Multimode communications fiber |

Others

|

Specialty Fiber

| Type | Application |

|---|---|

| Rare earth doped fibers | Optical amplifiers

|

| Rare earth doped fibers | Fiber lasers

|

| Rare earth doped fibers | Infrared Countermeasures |

| Rare earth doped fibers | Scintillating fibers |

| Rare earth doped fibers | Superluminescent sources |

|

Other doped fibers (dopants other than rare-earth ions) |

Fiber Bragg gratings (e.g., Ge-doped photosensitive fibers) |

| Other doped fibers (dopants other than rare-earth ions) | High-numerical-aperture fibers |

| Other doped fibers (dopants other than rare-earth ions) | Optical filters, wavelockers, ring resonators, other wavelength-control devices |

| Polarization-maintaining fibers | Inertial navigation (gyroscopes -- sensors for measuring angular movement / rate of rotation)

|

| Polarization-maintaining fibers | Other interferometric sensors (e.g., hydrophones, high-sensitivity temperature, electrical current, etc.) |

| Polarization-maintaining fibers | Dual-mode sensor systems (e.g., temperature+strain) |

| Polarization-maintaining fibers | Pigtails in high-performance S-M communication subsystems

|

| Double-clad fibers, multiple claddings | Specialty couplers |

| Double-clad fibers, multiple claddings | Fiber lasers, power amplifiers (especially for high-power systems) |

| Radiation resistance | Space communication laser systems (intra-satellite, satellite-to-satellite) |

| Radiation resistance | Tactical weapons systems |

| Special index profiles for control of waveguide properties | Applications:

|

| Fibers with special coating materials | Applications: Chemical sensing

Flame-retardency and other environmental properties |

| Fibers with combinations of dopants, polarization characteristics, specialty coatings, and special index profiles. | This group of specialty includes features of the types listed above, and the full range of their applications. |

| Large-core / large O.D borosilicate fibers |

|

(Both these tables represent a partial list of fiber types and applications, with examples selected to show the diversity of specialty fibers and applications)

Measuring fiber demand in kilometers or meters

As noted, the specialty fiber world has significantly more products and types on the market. Communication fibers, on the other hand, are produced in much greater quantities. In 2020, for example, global communication fiber installations exceeded 450 million kilometers.5 More than 90% of this total was ITU G.652.D “standard single-mode” fiber. The remainder included single-mode fibers complying with standards for improved dispersion, effective area, and bend performance as well as standard multimode fibers.

FOC estimates that total world demand for specialty fiber is on the order of one million km per year, or less than half a percent of communication fiber demand. Use of polarization-maintaining (PM) fiber in gyroscopes may extend into the hundreds of thousands of kilometers per year, but demand for other types is much lower. Many applications use just a few meters or even less than a meter in a sensor, fiber laser, or other device.

Bulk production vs. custom production

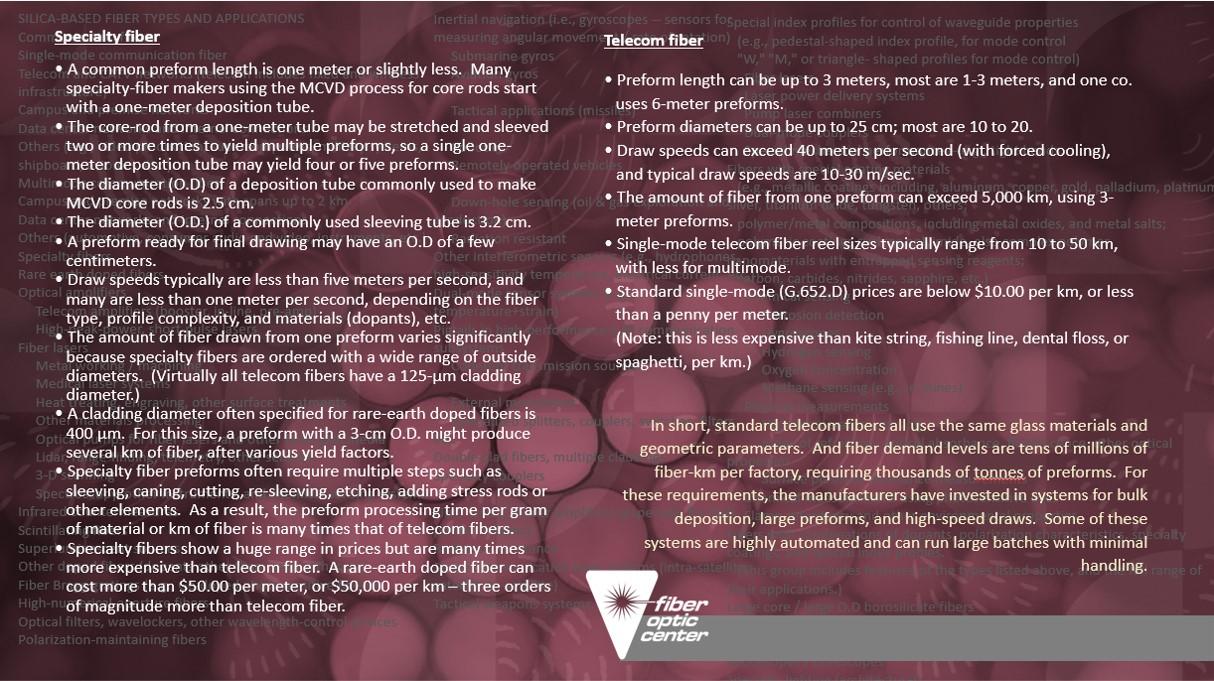

Most specialty fiber manufacturers offer many types, essentially filling a large number of small-quantity or custom orders. As a result, specialty fiber factories are not set up for bulk production in the way that telecom fiber is made. Some quick comparisons:

Telecom fiber

- Preform length can be up to 3 meters, most are 1-3 meters, and one co. uses 6-meter preforms.

- Preform diameters can be up to 25 cm; most are 10 to 20.

- Draw speeds can exceed 40 meters per second (with forced cooling), and typical draw speeds are 10-30 m/sec.

- The amount of fiber from one preform can exceed 5,000 km, using 3-meter preforms.

- Single-mode telecom fiber reel sizes typically range from 10 to 50 km, with less for multimode.

- Standard single-mode (G.652.D) prices are below $10.00 per km, or less than a penny per meter.

(Note: this is less expensive than kite string, fishing line, dental floss, or spaghetti, per km.)

Specialty fiber

- A common preform length is one meter or slightly less. Many specialty-fiber makers using the MCVD process for core rods start with a one-meter deposition tube

- The core-rod from a one-meter tube may be stretched and sleeved two or more times to yield multiple preforms, so a single one-meter deposition tube may yield four or five preforms.

- The diameter (O.D) of a deposition tube commonly used to make MCVD core rods is 2.5 cm.

- The diameter (O.D.) of a commonly used sleeving tube is 3.2 cm.

- A preform ready for final drawing may have an O.D of a few centimeters.

- Draw speeds typically are less than five meters per second, and many are less than one meter per second, depending on the fiber type, profile complexity, and materials (dopants), etc.

- The amount of fiber drawn from one preform varies significantly because specialty fibers are ordered with a wide range of outside diameters. (Virtually all telecom fibers have a 125-µm cladding diameter.)

- A cladding diameter often specified for rare-earth doped fibers is 400 µm. For this size, a preform with a 3-cm O.D. might produce several km of fiber, after various yield factors.

- Specialty fiber preforms often require multiple steps such as sleeving, caning, cutting, re-sleeving, etching, adding stress rods or other elements. As a result, the preform processing time per gram of material or km of fiber is many times that of telecom fibers.

- Specialty fibers show a huge range in prices but are many times more expensive than telecom fiber. A rare-earth doped fiber can cost more than $50.00 per meter, or $50,000 per km – three orders of magnitude more than telecom fiber.

In short, standard telecom fibers all use the same glass materials and geometric parameters. And fiber demand levels are tens of millions of fiber-km per factory, requiring thousands of tonnes of preforms. For these requirements, the manufacturers have invested in systems for bulk deposition, large preforms, and high-speed draws. Some of these systems are highly automated and can run large batches with minimal handling.

Specialty fibers are required in much smaller quantities, with more processing. The manufacturers do not need mass-production equipment. Their big requirement is highly skilled scientists, engineers, and technicians – deep expertise for the range of products and processing steps. Specialty fiber manufacturers often must research and prepare the starting chemicals, tailor the fiber design and production process to application requirements, conduct R&D on processing procedures, and troubleshoot production problems to make new or custom fibers.

Tailoring materials and geometric properties for different applications

Designing and fabricating fibers involves three key factors. The first is glass composition. The second is geometric characteristics – dimensions and shape. The third, refractive index profile, partially relies on the first two. That is, refractive index profile is determined by controlling where the different glass materials are placed in the fiber.

Glass composition is varied with different dopants. The goal is to control the fiber’s absorption, scattering, dispersion, and other phenomena at specific wavelengths. Control of the glass composition in different “parts” of the fiber further tailors the fiber’s performance over many parameters. By “parts,” we mainly mean concentric layers outward from the fiber’s central axis. (There are also some fibers with non-concentric parts, such as stress regions, cylindrical holes, voids, etc.)

This is where the size and geometric characteristics come in. The refractive index profile is a plot of the different materials’ refractive index over the distance from the center axis. The plot represents the refractive index for a cross-section of the fiber. The index can be modified with different dopants and different layer thicknesses to control loss, dispersion, bend performance, modal propagation, launch conditions, cut-off wavelength, and other optical properties.

In most fibers, the refractive index is symmetric — the fiber’s “features” are in concentric layers. Polarization-maintaining fibers, however, have asymmetric features to achieve birefringence. Unlike propagation in communication fibers, the goal in PM fibers to have two orthogonal polarization modes propagating separately. In many applications, the two modes are then recombined to measure the time delay, loss, or other perturbations for sensing various parameters. There are several ways to achieve the asymmetric features – using different materials to impart stress in the glass or using elliptical or other core and cladding shapes. These features require special fabrication processes.

Complex profiles and features raise manufacturing complexities

By controlling the materials, dimensions, and refractive index profile, the specialty fiber maker can tailor a fiber’s transmission, gain, birefringence, sensing properties, and other properties for different applications. These design options, however, also raise complex problems in fabricating the preforms and drawing the fibers.

The different glass materials and dopants have different coefficients of thermal expansion (CTE). In the MCVD process, the materials are deposited at high temperature and then cooled. Using materials with different CTEs introduces stress that complicates the handling and further processing of the MCVD core rod or preform.

Careful procedures are needed to avoid the risk of breaking core rods or preforms and to avoid introducing flaws that might cause problems in sleeving and drawing. The procedures vary with dopants and glass compositions as well as with index profiles and sizes. Working with different dopant concentrations and glass compositions also raises problems with the MCVD process –controlling the vapor pressure and deposition uniformity.

The incorporation of different dopants and the resulting stress factors also have implications on drawing. As noted, the outside diameters and coatings vary significantly among specialty fibers, so the draw process must address these complexities. In addition, the draw process must maintain the intended distribution of dopants and avoid introducing flaws, weaknesses, or other defects. This means the draw temperature, draw speed, preform-feed rate, pulling force, coating temperature, and other draw-tower variables must be carefully controlled.

Optimizing the MCVD process, managing the CTE stresses, and minimizing yield problems throughout the multi-step process requires extensive experience in working with different types of preforms. To help the specialty fiber industry, FOC has established a technical consulting service. We can review questions from specialty fiber manufacturers, users, and other industry participants to see where we can help in improving fiber processing and fiber performance.

1United Healthcare “Screen Time 2020 Report,” citing statistics from survey company Nielsen. (see www.eyesafe.com/uhc)

2Currently, telecom transmission equipment manufacturers offer systems that can launch 40, 80, 96, or more wavelengths into a single fiber. In the 1990s, 2.5-Gbps transmitters entered the market. By 2000, 10-Gbps transmitters were becoming well established, and 40 Gbps transmitters were demonstrated in 2004. Since then, R&D groups (and standards committees) have been developing transmitters based on coherent detection that achieve bit rates of 100, 200, 400, and even 800 Gbps.

3The ITU standards are numbered in a range from G.652 to G.657. Some of the standards in this series have two or more attributed classes designated by a letter. For example, G.652.D is the most widely used telecommunications fiber. Its main characteristics include zero dispersion at 1310 nm and low loss at 1550 nm. Other standards in the G.65x series cover dispersion-shifted, large-effective-area, and bend-insensitive fibers. The major fiber manufacturers participate in the ITU standards committees, and work on new specifications and enhancements is constantly underway.

4The ISO is an international organization. Its membership comprises the national standards bodies of 165 countries. The ISO’s IEC develops, publishes, and certifies standards in electrical and electronic technologies. The TIA FOTC standards for MM fibers were developed by the TIA-42 committee and are finalized as part of the ANSI/TIA 568 standards that cover structured cabling systems. The latest standard revision with the fiber specifications is ANSI/TIA 568.3-D. The corresponding ISO IEC standard numbers are ISO/IEC-11801-1. These standards define classes of 50/125-µm graded-index fiber with different launch, wavelength, and bandwidth characteristics. (A class of 62.5/125-µm graded-index fiber was included in earlier standards but is now considered obsolete in current revisions. It is still operating in legacy networks and supported by many manufacturers as needed.)

5CRU presented this estimate at its 6th World Optical Fibre and Cable Conference, October 26-28, 2020 (a virtual conference). This total is down from 512 million fiber-km installed in 2018, due to the Covid-19 pandemic and factors in key markets, such as China. In the 2020 conference, CRU forecast that total demand will surpass a half-billion fiber-km again in 2021.

This article is an original publication of Fiber Optic Center, Inc. It is shared publicly for educational and reference purposes to support learning and professional development within the fiber optics industry.

You are welcome to read, cite, or reference this material for non-commercial and educational purposes, as long as full credit is given to Fiber Optic Center, Inc. and the author.

Reuse, reproduction, or adaptation of this content — including rewriting, republishing, or incorporating it into new materials (such as websites, blogs, marketing text, technical guides, or AI-generated content) — is not permitted without prior written consent from Fiber Optic Center, Inc.

This material is protected by copyright law upon publication, even if not formally registered.

Use of this content for AI training, automated data extraction, or derivative content generation is prohibited.

Fiber Optic Center monitors and enforces the integrity of its intellectual property through digital identifiers and content tracking.

For more details, please refer to the Fiber Optic Center Content Use and Copyright policy.