Fiber Optic Center will be at OFC - Schedule your meeting with a member of the FOC team now

Final Lapping Film

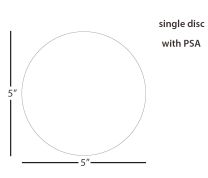

ÅngströmLap® Ultimas™-U Final Polish Lapping Film Disc - 5 inch

ÅngströmLap® Ultimas™-U Final Polish Lapping Film Disc - 5 inchThe ÅngströmLap® Ultimas™-U New Final Polish Lapping Film is designed to maintain ferrule geometry w...

Part: ULT02605503N100 FOS-022 Final Polish Lapping Film Disc, 5 inch

FOS-022 Final Polish Lapping Film Disc, 5 inchThe FOS-22 Final Polish Lapping Film is designed to maintain ferrule geometry while enhancing return...

Part: FOS-22 ÅngströmLap® Ultimas™-P New Final Polish Lapping Film Disc - 5 inch

ÅngströmLap® Ultimas™-P New Final Polish Lapping Film Disc - 5 inchThe ÅngströmLap® Ultimas™-P New Final Polish Lapping Film maintains the shape of the ferrule and imp...

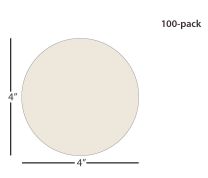

Part: ULT026FH503N100 ÅngströmLap® Ultimas™-P New Final Polish Lapping Film Disc - 4 inch

ÅngströmLap® Ultimas™-P New Final Polish Lapping Film Disc - 4 inchThe ÅngströmLap® Ultimas™-P New Final Polish Lapping Film maintains the shape of the ferrule and imp...

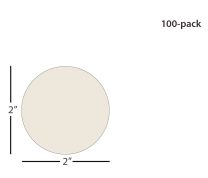

Part: ULT026FH403N100 ÅngströmLap® Ultimas™-P New Final Polish Lapping Film Disc - 2 inch

ÅngströmLap® Ultimas™-P New Final Polish Lapping Film Disc - 2 inchThe ÅngströmLap® Ultimas™-P New Final Polish Lapping Film maintains the shape of the ferrule and imp...

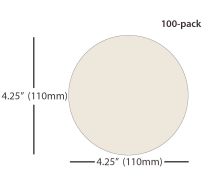

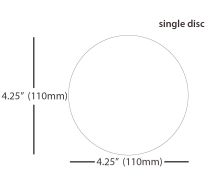

Part: ULT026FH203N100 ÅngströmLap® Ultimas™-P New Final Polish Lapping Film Disc - 110mm

ÅngströmLap® Ultimas™-P New Final Polish Lapping Film Disc - 110mmThe ÅngströmLap® Ultimas™-P New Final Polish Lapping Film maintains the shape of the ferrule and imp...

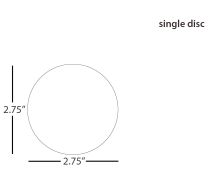

Part: ULT026FH1103N100 ÅngströmLap® Ultimas™-U Final Polish Lapping Film Disc - 2.75 inch

ÅngströmLap® Ultimas™-U Final Polish Lapping Film Disc - 2.75 inchThe ÅngströmLap® Ultimas™-U New Final Polish Lapping Film is designed to maintain ferrule geometry w...

Part: ULT02605273N100 ÅngströmLap® Ultimas™-U Final Polish Lapping Film Disc - 2 inch

ÅngströmLap® Ultimas™-U Final Polish Lapping Film Disc - 2 inchThe ÅngströmLap® Ultimas™-U New Final Polish Lapping Film is designed to maintain ferrule geometry w...

Part: ULT02605203N100 ÅngströmLap® Ultimas™-U Final Polish Lapping Film Disc - 110mm

ÅngströmLap® Ultimas™-U Final Polish Lapping Film Disc - 110mmThe ÅngströmLap® Ultimas™-U New Final Polish Lapping Film is designed to maintain ferrule geometry w...

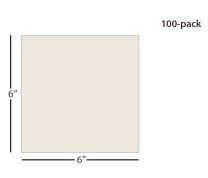

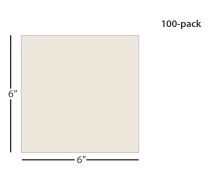

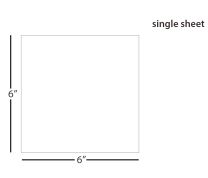

Part: ULT026051103N100 ÅngströmLap® Ultimas™-U Final Polish Lapping Film Sheet - 6 x 6 inch

ÅngströmLap® Ultimas™-U Final Polish Lapping Film Sheet - 6 x 6 inchThe ÅngströmLap® Ultimas™-U New Final Polish Lapping Film is designed to maintain ferrule geometry w...

Part: ULT02605663N100 AngstromLap® Ultimas™-P New Final Polish Lapping Film Sheet - 6 x 6 inch

AngstromLap® Ultimas™-P New Final Polish Lapping Film Sheet - 6 x 6 inchThe ÅngströmLap® Ultimas™-P New Final Polish Lapping Film maintains the shape of the ferrule and imp...

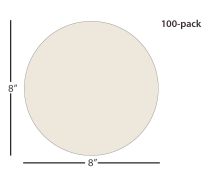

Part: ULT026FH663N100 ÅngströmLap® Ultimas™-P New Final Polish Lapping Film Disc - 8 inch

ÅngströmLap® Ultimas™-P New Final Polish Lapping Film Disc - 8 inchThe ÅngströmLap® Ultimas™-P New Final Polish Lapping Film maintains the shape of the ferrule and imp...

Part: ULT026FH803N100 ÅngströmLap® Ultimas™-U Final Polish Lapping Film Disc - 4 inch

ÅngströmLap® Ultimas™-U Final Polish Lapping Film Disc - 4 inchThe ÅngströmLap® Ultimas™-U New Final Polish Lapping Film is designed to maintain ferrule geometry w...

Part: ULT02605403N100 ÅngströmLap® Ultimas™-U Final Polish Lapping Film Disc - 8 inch

ÅngströmLap® Ultimas™-U Final Polish Lapping Film Disc - 8 inchThe ÅngströmLap® Ultimas™-U New Final Polish Lapping Film is designed to maintain ferrule geometry w...

Part: ULT02605803N100 3M™ 863XW Final Polish Lapping Film Disc - 5 inch

3M™ 863XW Final Polish Lapping Film Disc - 5 inch3M™ 863XW Final Polish Lapping Film is constructed with a precision-coated SiO2 mineral layer on a 3...

Part: 863XW-503N 3M™ 863X Final Polish Lapping Film Sheet - 6 x 6 inch

3M™ 863X Final Polish Lapping Film Sheet - 6 x 6 inch3M™ 863X Final Polish Lapping Film provides excellent fiber height control, but polishes more slowly...

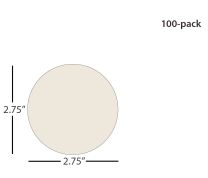

Part: 863X-663N 3M™ 863XW Final Polish Lapping Film Disc - 2.75 inch

3M™ 863XW Final Polish Lapping Film Disc - 2.75 inch3M™ 863XW Final Polish Lapping Film is constructed with a precision-coated SiO2 mineral layer on a 3...

Part: 863XW-273N 3M™ 865X Final Polish Lapping Film Disc - 2.75 inch

3M™ 865X Final Polish Lapping Film Disc - 2.75 inch3M™ 865X Final Polish Lapping Film features precision-coated SiO2 minerals on a 3 mil polyester film...

Part: 865X-273N 3M™ 869XW Final Polish Lapping Film Disc - 5 inch, PSA

3M™ 869XW Final Polish Lapping Film Disc - 5 inch, PSA3M™ 869XW Final Polish Lapping Film boasts a higher mineral content compared to 3M film 863X, enhanc...

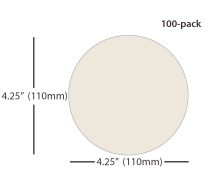

Part: 869XW-503P 3M™ 863XW Final Polish Lapping Film Disc - 4.25 inch

3M™ 863XW Final Polish Lapping Film Disc - 4.25 inch3M™ 863XW Final Polish Lapping Film is constructed with a precision-coated SiO2 mineral layer on a 3...

Part: 863XW-4253N 3M™ 863XW Final Polish Lapping Film Sheet - 6 x 6 inch

3M™ 863XW Final Polish Lapping Film Sheet - 6 x 6 inch3M™ 863XW Final Polish Lapping Film is constructed with a precision-coated SiO2 mineral layer on a 3...

Part: 863XW-663N 3M™ 865X Final Polish Lapping Film Sheet - 6 x 6 inch

3M™ 865X Final Polish Lapping Film Sheet - 6 x 6 inch3M™ 865X Final Polish Lapping Film features precision-coated SiO2 minerals on a 3 mil polyester film...

Part: 865X-663N Seikoh Giken 5" SiO2 Final Polish Lapping Film

Seikoh Giken 5" SiO2 Final Polish Lapping FilmThe Seikoh Giken Silicon Dioxide Final Polish Lapping Film maintains ferrule geometry while improvin...

Part: XF5D 3M™ 863X Final Polish Lapping Film Disc - 5 inch

3M™ 863X Final Polish Lapping Film Disc - 5 inch3M™ 863X Final Polish Lapping Film provides excellent fiber height control, but polishes more slowly...

Part: 863X-503N

Achieve -55dB Return Loss with Precision Final Polish Films

ÅngströmLap® SEQUOIA Final Polish Film is the latest from the ÅngströmLap® line of films. It was developed to reduce single mode assembly production consumables cost while maintaining the most stringent manufacturing processes in the industry; therefore, lot-to-lot product consistency is assured, enabling you to achieve uniform precision polishes, keeping yields at their maximum. SEQUOIA Final Polish Film outperforms the rest. Fiber Optic Center recommends final films for optimum, single mode and multimode performance but for a more economical, multimode process, Aluminum Oxide films from ÅngströmLap® may be substituted as final films.