Fiber Optic Center will be at OFC - Schedule your meeting with a member of the FOC team now

Lapping Film

ÅngströmLap® Silicon Carbide Lapping Film Disc - 5 inch 16µm (micron)

ÅngströmLap® Silicon Carbide Lapping Film Disc - 5 inch 16µm (micron)ÅngströmLap Silicon Carbide Lapping Film is a more aggressive abrasive film material, often recommen...

Part: SC16F503N100 ÅngströmLap® Sequoia Diamond Lapping Film Disc - 5 inch 5µm (micron)

ÅngströmLap® Sequoia Diamond Lapping Film Disc - 5 inch 5µm (micron)The ÅngströmLap Sequoia Diamond Lapping Film is an abrasive film used for polishing the end-face of ...

Part: D5BF503N1 ÅngströmLap® Sequoia Diamond Lapping Film Disc - 5 inch 1µm (micron)

ÅngströmLap® Sequoia Diamond Lapping Film Disc - 5 inch 1µm (micron)The ÅngströmLap Sequoia Diamond Lapping Film is an abrasive film used for polishing the end-face of ...

Part: D1KT503N1 ÅngströmLap® Ultimas™-U Final Polish Lapping Film Disc - 5 inch

ÅngströmLap® Ultimas™-U Final Polish Lapping Film Disc - 5 inchThe ÅngströmLap® Ultimas™-U New Final Polish Lapping Film is designed to maintain ferrule geometry w...

Part: ULT02605503N100 ÅngströmBrush® ABR70 Flock Pile Lapping Film Disc - 5 inch

ÅngströmBrush® ABR70 Flock Pile Lapping Film Disc - 5 inchThe ÅngströmBrush® ABR70 Flock Pile Lapping FIlm can be used as a cleaning pad in between each polis...

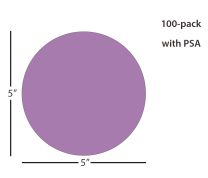

Part: ABR70NC502N1 ÅngströmLap® Silicon Carbide Lapping Film Disc - 5 inch 16µm (micron), PSA

ÅngströmLap® Silicon Carbide Lapping Film Disc - 5 inch 16µm (micron), PSAÅngströmLap Silicon Carbide Lapping Film is a more aggressive abrasive film material, often recommen...

Part: SC16F503P100 ÅngströmLap® MT EF Silicon Carbide Lapping Film Disc - 5 inch 3µm (micron), PSA

ÅngströmLap® MT EF Silicon Carbide Lapping Film Disc - 5 inch 3µm (micron), PSAÅngströmLap® Silicon Carbide Lapping Film is a more aggressive abrasive film material, often recomme...

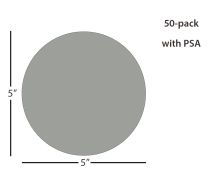

Part: SC3EF503P100 ÅngströmBrush® Aluminum Oxide Flock Pile Lapping Film - 5 inch 1µm (micron), PSA

ÅngströmBrush® Aluminum Oxide Flock Pile Lapping Film - 5 inch 1µm (micron), PSAThe ÅngströmBrush® Aluminum Oxide Flock Pile Lapping FIlm can be used as a cleaning pad in between e...

Part: AA1MFPS502P50 ÅngströmBrush® Ultimas™-F SiOx Flock Pile Lapping Film Disc - 5 inch, PSA

ÅngströmBrush® Ultimas™-F SiOx Flock Pile Lapping Film Disc - 5 inch, PSAThe ÅngströmBrush® Ultimas™-F SiOx Flock Pile Lapping Film is designed to consistently polish irregu...

Part: ULT26MFPG502P50 FOS-022 Final Polish Lapping Film Disc, 5 inch

FOS-022 Final Polish Lapping Film Disc, 5 inchThe FOS-22 Final Polish Lapping Film is designed to maintain ferrule geometry while enhancing return...

Part: FOS-22 ÅngströmLap® Ultimas™-P New Final Polish Lapping Film Disc - 5 inch

ÅngströmLap® Ultimas™-P New Final Polish Lapping Film Disc - 5 inchThe ÅngströmLap® Ultimas™-P New Final Polish Lapping Film maintains the shape of the ferrule and imp...

Part: ULT026FH503N100 ÅngströmLap® Sequoia Diamond Lapping Film Disc - 5 inch 3µm (micron)

ÅngströmLap® Sequoia Diamond Lapping Film Disc - 5 inch 3µm (micron)The ÅngströmLap Sequoia Diamond Lapping Film is an abrasive film used for polishing the end-face of ...

Part: D3AT503N1 ÅngströmLap® Sequoia Diamond Lapping Film Disc - 5 inch 9µm (micron)

ÅngströmLap® Sequoia Diamond Lapping Film Disc - 5 inch 9µm (micron)The ÅngströmLap Sequoia Diamond Lapping Film is an abrasive film used for polishing the end-face of ...

Part: D9KF503N1 ÅngströmLap® Silicon Carbide Lapping Film Disc - 5 inch 40µm (micron)

ÅngströmLap® Silicon Carbide Lapping Film Disc - 5 inch 40µm (micron)ÅngströmLap Silicon Carbide Lapping Film is a more aggressive abrasive film material, often recommen...

Part: SC40F503N100 ÅngströmLap® Silicon Carbide Lapping Film Disc - 5 inch 30µm (micron)

ÅngströmLap® Silicon Carbide Lapping Film Disc - 5 inch 30µm (micron)ÅngströmLap® Silicon Carbide Lapping Film is a more aggressive abrasive film material, often recomme...

Part: SC30F503N100 ÅngströmLap® Sequoia Diamond Lapping Film Disc - 5 inch 30µm (micron), PSA

ÅngströmLap® Sequoia Diamond Lapping Film Disc - 5 inch 30µm (micron), PSAThe ÅngströmLap Sequoia Diamond Lapping Film is an abrasive film used for polishing the end-face of ...

Part: D30NW503P1 ÅngströmLap® Aluminum Oxide Lapping Film Disc - 5 inch 30µm (micron)

ÅngströmLap® Aluminum Oxide Lapping Film Disc - 5 inch 30µm (micron)ÅngströmLap Aluminum Oxide Lapping Film is recommended when diamond lapping film is not needed, like...

Part: AO30F503N100 ÅngströmLap® Aluminum Oxide Lapping Film Disc - 5 inch 30µm (micron), PSA

ÅngströmLap® Aluminum Oxide Lapping Film Disc - 5 inch 30µm (micron), PSAÅngströmLap Aluminum Oxide Lapping Film is recommended when diamond lapping film is not needed, like...

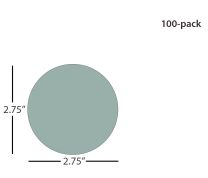

Part: AO30F503P100 ÅngströmLap® Silicon Carbide Lapping Film Disc - 2.75 inch 30µm (micron)

ÅngströmLap® Silicon Carbide Lapping Film Disc - 2.75 inch 30µm (micron)ÅngströmLap® Silicon Carbide Lapping Film is a more aggressive abrasive film material, often recomme...

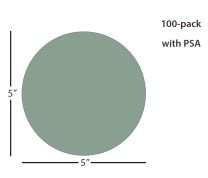

Part: SC30F273N100 ÅngströmLap® Silicon Carbide Lapping Film Disc - 5 inch 30µm (micron), PSA

ÅngströmLap® Silicon Carbide Lapping Film Disc - 5 inch 30µm (micron), PSAÅngströmLap® Silicon Carbide Lapping Film is a more aggressive abrasive film material, often recomme...

Part: SC30F503P100 ÅngströmBrush® Silicon Carbide Flock Pile Lapping Film - 5 inch 3µm (micron), PSA

ÅngströmBrush® Silicon Carbide Flock Pile Lapping Film - 5 inch 3µm (micron), PSAThe ÅngströmBrush® Silicon Carbide Flock Pile Lapping FIlm is an abrasive pad with 3-5/mm fibers coa...

Part: SC3PWBH502P50 ÅngströmLap® Calcined Alumina Lapping Film Disc - 5 inch 0.3µm (micron), PSA

ÅngströmLap® Calcined Alumina Lapping Film Disc - 5 inch 0.3µm (micron), PSAThe ÅngströmLap® Calcined Alumina Lapping Film is an Aluminum Oxide-based 0.3µm lapping film primari...

Part: CA03T503P100 ÅngströmLap® Sequoia Stick Silicon Disc - 5 inch, PSA

ÅngströmLap® Sequoia Stick Silicon Disc - 5 inch, PSAThe ÅngströmLap® Sequoia Stick Silicon Disc consists of one side made of silicon, where lapping film...

Part: SSTK-50-1 ÅngströmLap® MT EF Silicon Carbide Lapping Film Disc - 5 inch 3µm (micron)

ÅngströmLap® MT EF Silicon Carbide Lapping Film Disc - 5 inch 3µm (micron)ÅngströmLap® Silicon Carbide Lapping Film is a more aggressive abrasive film material, often recomme...

Part: SC3EF503N100

Control Production Costs by Choosing the Right Lapping Film

Achieving consistent results that meet the demanding technical specifications for single mode systems requires the optimization of many factors throughout the termination and testing process.

Fiber Optic Center can supply detailed polishing instructions for most commercially available fiber optic polishing machines and offers lapping film in the following areas: Diamond Lapping Film, Final Lapping Film, Aluminum Oxide Lapping Film, Silicon Carbide Lapping Film, Abrasive, Coated Flock Pile Film, Cleaning Film (Non-abrasive Flock Pile Film), Slurries and all ÅngströmLap Films.

Special Note on PSA - Pressure Sensitive Adhesive: Pressure Sensitive Adhesive is only recommended when it is completely necessary. Once the film is stuck to the polish surface, it cannot be removed and reused. The adhesive also creates a potential and likely problem of debris adhering to the film that cannot be removed. Any debris that comes in contact with the fiber may cause a scratch. PSA will also increase the cost of the lapping film. The films shown here are typical stock items. However, if you do not find the right size/material configuration, including center holes or PSA, to fit your application, we may already have it or we can have it manufactured for you. Please contact Fiber Optic Center with any request.