Fiber Optic Center will be at OFC - Schedule your meeting with a member of the FOC team now

Epoxy Curing Equipment

Domaille CO-6500 Epoxy Curing Oven with TMT Tray - 110V

Domaille CO-6500 Epoxy Curing Oven with TMT Tray - 110VThe Domaille Engineering CO-6500 Universal Epoxy Curing Oven (110/120V) featuring a 24-position TMT ...

Part: CO-6500-TMT Domaille CO-6700 Programmable Epoxy Curing Oven with Vertical Tray for Molex Sleeves - 110V

Domaille CO-6700 Programmable Epoxy Curing Oven with Vertical Tray for Molex Sleeves - 110VThe Domaille Engineering CO-6700 Universal Epoxy Curing Oven (110V/120V), featuring a 48-position Ve...

Part: CO-6700-V2 Domaille CO-6800 Programmable Epoxy Curing Oven with Vertical Tray for Molex Sleeves - 220V

Domaille CO-6800 Programmable Epoxy Curing Oven with Vertical Tray for Molex Sleeves - 220VThe Domaille Engineering CO-6800 Universal Epoxy Curing Oven (220V/240V), featuring a 48-position Ve...

Part: CO-6800-V2 Dymax BlueWave® 200 UV Curing Spot Lamp with Foot Switch (V3.1)

Dymax BlueWave® 200 UV Curing Spot Lamp with Foot Switch (V3.1)The Dymax BlueWave® 200 UV Epoxy Curing Spot Lamp version 3.1 is a high-intensity, light-curing syst...

Part: 41015 Dymax 2000-EC UV Curing Flood Lamp

Dymax 2000-EC UV Curing Flood LampThe Dymax 2000-EC Series UV Epoxy Curing Flood Lamps provide moderate to high-intensity UV light cur...

Part: 38105 Dymax 5000-EC UV Curing Flood Lamp

Dymax 5000-EC UV Curing Flood LampThe Dymax 5000-EC Series UV Epoxy Curing Flood Lamps provide moderate to high-intensity UV light cur...

Part: 38100 Domaille CO-6800 Programmable Epoxy Curing Oven with TMT Tray - 220V

Domaille CO-6800 Programmable Epoxy Curing Oven with TMT Tray - 220VThe Domaille Engineering CO-6800 Programmable Epoxy Curing Oven (220V/240V), featuring a 24-position...

Part: CO-6800-TMT Domaille CO-6700 Programmable Epoxy Curing Oven with TMT Tray - 110V

Domaille CO-6700 Programmable Epoxy Curing Oven with TMT Tray - 110VThe Domaille Engineering CO-6700 Programmable Epoxy Curing Oven (110V/120V), featuring a 24-position...

Part: CO-6700-TMT Domaille CO-6600 Epoxy Curing Oven with TMT Tray - 220V

Domaille CO-6600 Epoxy Curing Oven with TMT Tray - 220VThe Domaille Engineering CO-6600 Universal Epoxy Curing Oven (220V/240V) featuring a 24-position TMT...

Part: CO-6600-TMT Domaille CO-6600 Epoxy Curing Oven with Vertical Tray for Molex Sleeves - 220V

Domaille CO-6600 Epoxy Curing Oven with Vertical Tray for Molex Sleeves - 220VThe Domaille Engineering CO-6600 Universal Epoxy Curing Oven (220V/240V) featuring an MT 48-position...

Part: CO-6600-V2 Domaille CO-6500 Epoxy Curing Oven with MT Tray - 110V

Domaille CO-6500 Epoxy Curing Oven with MT Tray - 110VThe Domaille Engineering CO-6500 Universal Epoxy Curing Oven (110/120V) featuring an MT 24-position ...

Part: CO-6500-MT Domaille CO-6800 Programmable Epoxy Curing Oven with MT Tray - 220V

Domaille CO-6800 Programmable Epoxy Curing Oven with MT Tray - 220VThe Domaille Engineering CO-6800 Universal Epoxy Curing Oven (220V/240V) with 48-position MT Horizon...

Part: CO-6800-MT Labnet AccuBlock™ 96-Port Digital Dry Bath - 230V

Labnet AccuBlock™ 96-Port Digital Dry Bath - 230VThe Labnet AccuBlock™ Digital Dry Bath Incubator (D1301-230V) is designed for heating samples in tub...

Part: D1301-230V-96 Labnet AccuBlock™ 48-Port Digital Dry Bath - 230V

Labnet AccuBlock™ 48-Port Digital Dry Bath - 230VThe Labnet AccuBlock™ Digital Dry Bath Incubator (D1301-230V) is designed for heating samples in tub...

Part: D1301-230V-48 Agiltron UV LED Curing Spot Lamp (365nm) with Foot Pedal

Agiltron UV LED Curing Spot Lamp (365nm) with Foot PedalThe Agiltron Ultra High Power UV LED Curing System offers a cost-effective, long-lasting, and energy...

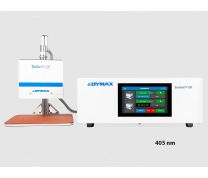

Part: SUVA-011NNNNN1 Dymax BlueWave® FX-1250 High Intensity LED Curing Flood System - 405nm

Dymax BlueWave® FX-1250 High Intensity LED Curing Flood System - 405nmThe Dymax BlueWave® FX-125 High Intensity LED Epoxy Curing Flood System (385nm) delivers true, high-...

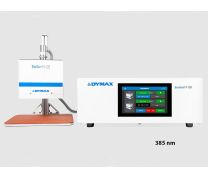

Part: 88855 Dymax BlueWave® FX-1250 High Intensity LED Curing Flood System - 385nm

Dymax BlueWave® FX-1250 High Intensity LED Curing Flood System - 385nmThe Dymax BlueWave® FX-125 High Intensity LED Epoxy Curing Flood System (385nm) delivers true, high-...

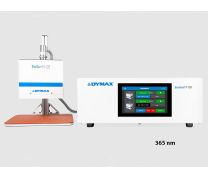

Part: 88849 Dymax BlueWave® FX-1250 High Intensity LED Curing Flood System - 365nm

Dymax BlueWave® FX-1250 High Intensity LED Curing Flood System - 365nmThe Dymax BlueWave® FX-125 High Intensity LED Epoxy Curing Flood System (365nm) delivers true, high-...

Part: 88848 Dymax BlueWave® MX-150 LED Curing Spot Lamp 2-Channel Controller

Dymax BlueWave® MX-150 LED Curing Spot Lamp 2-Channel ControllerThe Dymax BlueWave® MX-150 LED Epoxy Curing Spot Lamp is comprised of two main parts, a controller w...

Part: 43185 Labnet AccuBlock™ 24-Port Digital Dry Bath - 230V

Labnet AccuBlock™ 24-Port Digital Dry Bath - 230VThe Labnet AccuBlock™ Digital Dry Bath with a single-block 230V configuration offers precise tempera...

Part: D1301-230V-24 AccuCure™ 96-Port Fiber Optic Epoxy Curing Oven - 110V

AccuCure™ 96-Port Fiber Optic Epoxy Curing Oven - 110VThe AccuCure™ 96-Position Epoxy Curing Oven for fiber optic connectors has been designed using the l...

Part: ACD-96 AccuCure™ 48-Port Fiber Optic Epoxy Curing Oven - 110V

AccuCure™ 48-Port Fiber Optic Epoxy Curing Oven - 110VThe AccuCure™ 48-Position Epoxy Curing Oven for fiber optic connectors has been designed using the l...

Part: ACD-48 AccuCure™ 24-Port Fiber Optic Epoxy Curing Oven - 110V

AccuCure™ 24-Port Fiber Optic Epoxy Curing Oven - 110VThe AccuCure™ 24-Position Epoxy Curing Oven for fiber optic connectors has been designed using the l...

Part: ACD-24 Domaille CO-6500 Epoxy Curing Oven with Vertical Tray for Molex Sleeves - 110V

Domaille CO-6500 Epoxy Curing Oven with Vertical Tray for Molex Sleeves - 110VThe Domaille Engineering CO-6500 Universal Epoxy Curing Oven (110/120V) featuring a 48-position Vert...

Part: CO-6500-V2

Epoxy Curing Equipment

Epoxies and UV curing systems used in fiber optics devices require superior bonding strength and excellent optical clarity. We distribute easy to use 2-part packets, premixed and frozen syringes or cartridges, jars, vials, quarts, gallons, or other specialty packing that ensure the correct ratio of fiber optic epoxy to hardener, long pot life and a wide range of curing conditions and solutions for any requirement. Fiber Optic Center’s epoxy technical expert provides product selection assistance with all physical properties, application directions and handling characteristics.