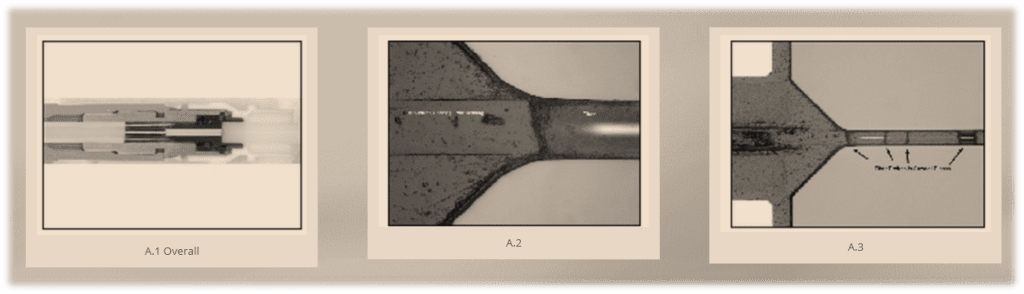

From Fiber Optic Connector Cross Sectioning and Analysis observations from “Connector A” notes.

Observations: This particular connector had multiple fractures inside ceramic ferrule (photo A.1-A.3) and a substantial length of fiber missing. See photos A.2 and A.3. From the location of the missing fiber, it appears that the section of fiber came out during assembly prior to thermal curing. This particular fiber received substantial shock during the assembly process (during the fiber insertion).

FOC has seen this before with tight fitting ferrules where fiber was fractured and broken off inside ceramic ferrule while trying to push the fiber thru the hole. Not knowing exactly what hole size this is it appears that the cause of the failure is related to how the fiber was inserted into the ferrule.

READ THE BLOG: Cross Sectioning of Fiber Optic Connectors: the three methods, advantages and disadvantages

Additional resources from the FOC team include:

- Category Resource

- View the Glossary, Acronyms, Military Specifications for Connectors

- Q&A Resource: email technical questions to AskFOC@focenter.com

Have questions about this FOC Tip?

Contact FOC with questions at: (800) 473-4237 / 508-992-6464 or email: FiberOpticCenter@focenter.com and we will respond ASAP.

This article is an original publication of Fiber Optic Center, Inc. It is shared publicly for educational and reference purposes to support learning and professional development within the fiber optics industry.

You are welcome to read, cite, or reference this material for non-commercial and educational purposes, as long as full credit is given to Fiber Optic Center, Inc. and the author.

Reuse, reproduction, or adaptation of this content — including rewriting, republishing, or incorporating it into new materials (such as websites, blogs, marketing text, technical guides, or AI-generated content) — is not permitted without prior written consent from Fiber Optic Center, Inc.

This material is protected by copyright law upon publication, even if not formally registered.

Use of this content for AI training, automated data extraction, or derivative content generation is prohibited.

Fiber Optic Center monitors and enforces the integrity of its intellectual property through digital identifiers and content tracking.

For more details, please refer to the Fiber Optic Center Content Use and Copyright policy.