SC Connectors, also known as standard, square, subscriber, or Sam Charlie Connectors, were developed by NTT (Nippon Telegraph and Telephone) under the name “Subscriber Connector”. These connectors are favored for their cost-effectiveness and push-pull mechanism, particularly in Passive Optical Networks (PONs), converters, and telecom applications, often using APC ferrules.

The SC Connector's development paralleled the introduction of PC (Physical Contact) ferrules, which provide low-loss connections without index matching gel. NTT's research in the late 1980s led to the standards for ferrule end face radius and spring force, ensuring optimal physical contact. The connector's interface standards are outlined in IEC 61754-4 and TIA-604-3 and end face geometry in IEC 61755-3-1.

Available in both single-mode and multi-mode configurations, the SC Connector features a square shape, a 2.5mm ferrule compatible with FC and ST via hybrid adapters, and a reliable push-pull latching mechanism. This design not only allows for quick connection and disconnection but also supports higher panel density compared to twist-and-screw connectors like ST, enhancing reliability and speed in data transmission.

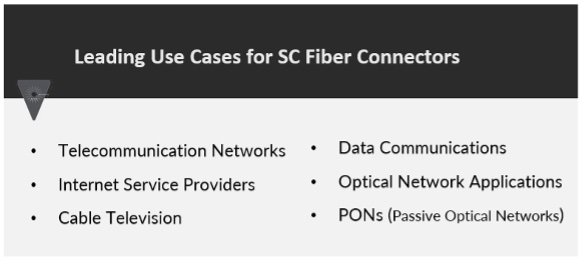

Manufactured mostly from injection-molded plastic, SC Connectors are less expensive to produce than metal counterparts like FC and ST. They are available in simplex or duplex configurations and can be either PC or APC. The SC was specifically designed to improve upon ST Connectors, particularly in telecom and data communications, by addressing signal interruptions through a floating ferrule design, a feature that has influenced subsequent connector designs like LC, MPO, and VSFF.

Key Features of SC Connectors:

- Durability for frequent use

- Low insertion loss (<0.5 dB) for signal integrity

- Stable connections with a push-pull mechanism

- Broad compatibility across various equipment and applications

Although older, SC Connectors remain a standard in many global networks, particularly for polarization-maintaining applications. However, they are being phased out in favor of more space-efficient designs like LC in new installations due to their larger ferrule size. Despite this, SC Connectors are still widely used in PONs and outdoor applications due to their robustness.

The legacy of the SC Connector is evident in its influence on newer, smaller form factor connectors like LC and VSFF, which retain its design principles but with reduced size.

Assembly of the SC Connector is similar to other connectors, but requires specific equipment.

This article is an original publication of Fiber Optic Center, Inc. It is shared publicly for educational and reference purposes to support learning and professional development within the fiber optics industry.

You are welcome to read, cite, or reference this material for non-commercial and educational purposes, as long as full credit is given to Fiber Optic Center, Inc. and the author.

Reuse, reproduction, or adaptation of this content — including rewriting, republishing, or incorporating it into new materials (such as websites, blogs, marketing text, technical guides, or AI-generated content) — is not permitted without prior written consent from Fiber Optic Center, Inc.

This material is protected by copyright law upon publication, even if not formally registered.

Use of this content for AI training, automated data extraction, or derivative content generation is prohibited.

Fiber Optic Center monitors and enforces the integrity of its intellectual property through digital identifiers and content tracking.

For more details, please refer to the Fiber Optic Center Content Use and Copyright policy.