Reflecting on trade show booths and poster papers now versus the past few years, I believe that we are ready for disruptive change. Every year there are many new disruptive technologies being put forth as ready for implementation. The real question is, are those changes and technologies being presented ready to be accepted?

Some of the radical concept products that have been presented over the last 20 years look like they would disrupt the existing technologies but did not. A couple of examples the Amp Optimate connectors the biconic connector, slotted core cables, snap in cables, etc.

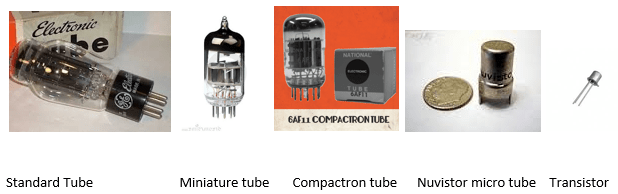

However, many of these are only a footnote in the history of fiber optics. The more I look at how things have changed the more I see they have stayed the same, I am reminded of a similar technology path taken by other products in years past. The easiest example I can provide and one that I grew up with was the transition from vacuum tubes to transistors and eventually integrated circuits. If you look at the earliest commercial vacuum tubes in the 1920s and 1930s you see simple single action triode tubes that were basically a variable valve.

In fact the British referred to vacuum tubes as valves. Over time the pentode tube replaced the triode and the diode tubes in more sophisticated applications. In due time a newfangled device was invented called the transistor. The earliest transistors had very limited current and voltage handling characteristics, however, they could mimic the function of the vacuum tube very well but they were finicky and difficult to handle. They were very sensitive to the heat of a soldering iron and static electricity.

At this point in time the vacuum tube was becoming more and more sophisticated with the development of compactrons, these tubes were actually several tubes in one vacuum envelope with many more connections out with a single filament so less energy usage meant more efficient vacuum tubes.

They were extremely robust to handle and use but still required high voltage DC and filament power to operate, things the transistor did not need. By the time the transistor came on the market place the vacuum tube had become very efficient and their evolution was significant. While transistors found commercial acceptance in things like portable radios, The vacuum tube industry literally built a miniature tube called a Nuvistor. This miniature tube had a metal case and looked like a slightly oversized transistor. It’s energy usage for filaments and DC voltage was significantly lower than previous vacuum tubes. It was easier to handle more rugged and installable.

The transistor still in its infancy was becoming smaller, able to handle more power with less energy usage and was finding better and newer applications especially in the low-power and portable markets. Eventually this disruptive technology borrowed some of the best Ideas from the vacuum tube world such as putting multiple junctions on a single chip much like the compactron put multiple tubes in a single vacuum and filament envelope. As it became clear that the cost features of transistors would drop significantly below the vacuum tube basic costs it became a rapid and wholesale conversion from vacuum tube technology to solid-state technology.

Today we still assemble fiber-optic cables and connectors basically the way we did in 1980 that’s 36 years ago so some of you folks who read this may not have even been around when the process you use today was first developed. We still assemble cables with strength members independent of our jackets, buffers and optical fibers. This is somewhat akin to the original copper wire insulation of braided cotton over rubber that was used until plastic compounds became available.

So, what was the tipping point?

It’s my belief based upon seeing the industry as a whole today after 38+ years that the tipping point occurs when the lowest total installed cost is achieved. This is not my concept but one I learned years ago from a colleague who also has many years in this industry, Eric Pearson. Basically stated, people will not change processes until they have a pathway to a lower cost solution. There are multiple parts to achieving this. They must feel a high comfort level with achieving success in the new process. The cost of raw materials needs to be sustainably lower than the present processes, They need to see a clear path to continue to improve the new process and also that their comfort level that the finished product will perform as well as or better than the product process it’s replacing.

As I look around at the technical papers and projects presented at OFC this year I could finally ask the important questions: how difficult is it to do and how much does it cost? The differentiator this year is that the products are cost-effective now, the performance of the products is being tested against significantly increased industry standards and the ability to learn this process especially for a new generation of fiber optic engineers and technicians is pretty straightforward.

How come this is occurring now?

A number of industries outside of our own have become enablers. These enablers are not limited to our industry alone but have the volume of being a part of many industries to encourage rapid development. Many of the software technologies have started the tipping process by changing the way we design and build the basic level of our infrastructure; cables, cable assemblies and connectors. I also note this change in the network architecture. Although I work primarily in the physical layer and am less well acquainted at the higher level such as passive optical network solutions, many new technologies have made the jump to commercialization and will replace existing technologies. This will allow for rapid dissemination of highly efficient bandwidth loaded passive optical networks at very affordable costs.

With the cable and connector industry as an example disruptive technologies as opposed to existing product and process evolution have pushed us well past the time to update our concepts of how to build the physical layer. By this time in product life cycles most processes are automated and widely accepted as better quality than manual processes. We still put connectors on by hand one at a time glue them in with epoxy and crimp aramid type yarns to reinforce a lack of strength in cable connector interfaces.

One important point about the legacy products descriptor. Even after transistors and integrated circuits became the new normal many specialized applications continued to use legacy products. Vacuum tubes were used in many applications and continued to be a replacement product for almost 30 years after the transistor became the preferred building block of circuits. I don’t think existing cables designs, existing connector designs or the way we assemble them will disappear overnight. What I believe is starting to happen is that they will become the old time standard against which many of the new technologies are measured. Both in performance and particularly in quality. And these new processes will continue to show improved performance and usability.

Another example is the migration from mini computers to the PC. While most businesses were cautious about the IBM PC it’s functionality soon convinced even the hardliners that the newer solution had the lowest total installed cost. Yet mini computers such as the DEC PDP 11 continued in existence for over a dozen years after the PC became the new normal. That said it’s important to recognize the evolution of the cable and connector assemblies we have today from the early ones in the 1980s.

There is significant improvement just as there was in the vacuum tube world and I believe that many of the newest technologies including things such as 3-D printing, the ability to print optical circuits and to build viable LEDs on a chip have enhanced and forced the industries hand into changing and finally making some significant changes in the way we do things.