Fiber Optic Center will be at OFC - Schedule your meeting with a member of the FOC team now

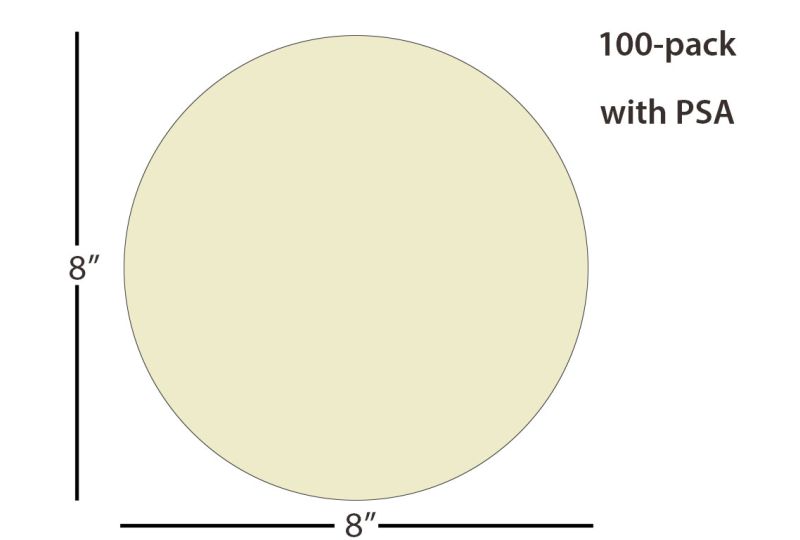

ÅngströmLap® Aluminum Oxide Lapping Film Disc - 8 inch 0.5µm (micron), PSA

AO05F803P100

Aluminum Oxide 0.5µm lapping film is typically used as a final film for MM connectors. To achieve the best finish with 0.5um AlOx, FOC recommends using it with Ultra Polish Solution. When used with the Ultra Polish Solution, it will give a near flawless finish.

The 8" film disc is the standard size for the Ultra Tec Ultrapol 1200, some Buelher Polishing Machines, as well as others.

Lapping Film Features:

- Film Color: White

- Tape Total Thickness: 86.0 ± 2.0 µm

- Surface Roughness: 0.18 ± 0.04 µm

- Particle Type: Aluminum Oxide film

- Grit Size: 0.5 micron (0.5 µm)

- Base Film Material: Polyethylene terephthalate

- Base Film Thickness: 3 mil (75 µm)

- Quantity: 100 discs

- Process Parameters Type: CF

- PSA Backed Film

- Product Life: Guaranteed up to 5 years from the manufactured date

Datasheet

Product Video

Updates

Effective June 2025, the packaging of the ÅngströmLap® polishing film will be changed to a perforated packaging type from the previous zip packaging.

This is for all ÅngströmLap® products with a size of 5 inches or less.

For ÅngströmLap® products with a size of 6 inches or more, the packaging may be changed depending on if the back side is processed or not.

We are excited for these changes to:

- Improve efficiency of mass production by changing packaging

- Provide environmentally friendly packaging process

- Prevent packaging errors

If you have any questions, please feel free to contact the FOC sales staff!

Fiber Optic Center

4.9 71 Google reviews

Represents overall Google Reviews of Fiber Optic Center, Inc.

Content Use Notice:

This product detail page and its content are the property of Fiber Optic Center, Inc. and are provided for informational and evaluation purposes.

You may view or reference this page for non-commercial use with proper attribution. Copying, rewriting, republishing, scraping, or using this content to produce new or modified content, including AI-generated content, is not permitted without written permission.

This content is protected by copyright law upon publication. Learn more