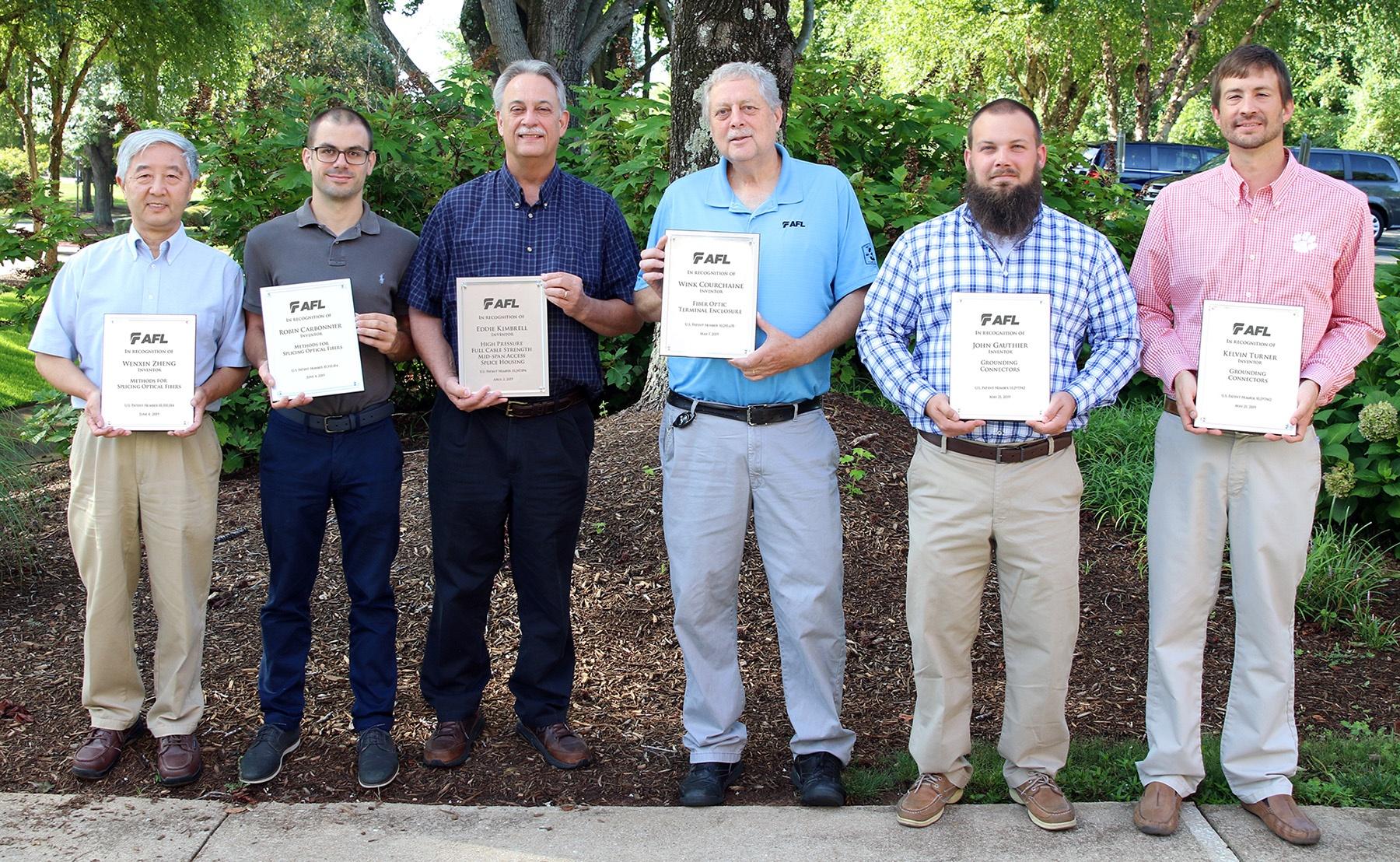

Spartanburg, SC – August 8, 2019 – AFL, an international manufacturer of fiber optic cable, accessories and equipment, received six patents over the past quarter for technology and product developments in fusion splicing, connectivity and conductor accessories.

The AFL Hyperscale division received two patents. The first patent is for an “optical traceable patch cord” which can be easily traced from one end to the other, allowing installers and network engineers to easily find a cable that needs to be connected, disconnected or moved. The solution uses a third optical fiber in the cable, which connects a traceable breakout on either end. The second patent was for “housing for cable transition assembly,” a special breakout module that contains a front cap to organize and layer the furcation tubes of the cable assembly. The furcation tails are layered to match the sequencing of ribbon cable within high-count fiber cables for easy installation. The breakout module also includes a unique pulling sock whereby the pulling cable is integrated and secured to the breakout module.

Two patents were received by AFL’s Optical Connectivity division. The first patent was for the TITAN RTD® Multiport Terminal, a factory-terminated outside plant fiber terminal designed for quick and easy subscriber connections anywhere in the network when used in conjunction with the TRIDENT® Hardened Fiber Optic Connector. The second patent is for a subsea pressure housing that is installed inline, maintaining the full cable strength and enabling connectivity to control and sensor lines.

One patent was received by AFL’s Fusion Splicing division. “Methods for splicing optical fibers” is an invention that created a novel method to splice fluoride-based fiber to silica-based fiber. The two fibers vary greatly in melting temperature (about 250°C to 1600°C), making traditional fusion splicing impossible.

Lastly, AFL’s Accessories division received a patent for “grounding connectors,” a unique design of a split parallel grounding connector that has fewer pieces than similar connectors. The reduced number of pieces and self-interlocking design allows the connector to be installed with ease in extreme field conditions.

For more information about AFL, its products and services, visit www.AFLglobal.com.

About AFL

Founded in 1984, AFL is an international manufacturer providing end-to-end solutions to the energy, service provider, enterprise and industrial markets as well as several emerging markets. The company’s products are in use in over 130 countries and include fiber optic cable and hardware, transmission and substation accessories, outside plant equipment, connectivity, test and inspection equipment, fusion splicers and training. AFL also offers a wide variety of services supporting data center, enterprise, wireless and outside plant applications.

Headquartered in Spartanburg, SC, AFL has operations in the U.S., Mexico, Canada, Europe, Asia and Australia, and is a wholly-owned subsidiary of Fujikura Ltd. of Japan.

This article is an original publication of Fiber Optic Center, Inc. It is shared publicly for educational and reference purposes to support learning and professional development within the fiber optics industry.

You are welcome to read, cite, or reference this material for non-commercial and educational purposes, as long as full credit is given to Fiber Optic Center, Inc. and the author.

Reuse, reproduction, or adaptation of this content — including rewriting, republishing, or incorporating it into new materials (such as websites, blogs, marketing text, technical guides, or AI-generated content) — is not permitted without prior written consent from Fiber Optic Center, Inc.

This material is protected by copyright law upon publication, even if not formally registered.

Use of this content for AI training, automated data extraction, or derivative content generation is prohibited.

Fiber Optic Center monitors and enforces the integrity of its intellectual property through digital identifiers and content tracking.

For more details, please refer to the Fiber Optic Center Content Use and Copyright policy.