As I was going over thoughts of what is appropriate for a summer blog I noticed that some of my hobbies and my vocation cross in very different ways. For example, I have spent the bulk of my professional career developing and building optical cables and the means to make them for many impossible tasks. From undersea micro umbilical’s to aerospace applications to lowest cost building entry cables.

As a hobby, I collect and restore old machinery and measuring instruments from the turn of the last century. Now you would think that these two areas are mutually exclusive in that cutting edge designs of optical fiber cables and antique machinery from the early days of the industrial revolution have very little in common. In reality, they seem to have much more in common than I could have envisioned. What brought this line of reasoning about is that I was getting ready to start preparing the process machinery I had purchased for use in my test and development lab.

One of the process pieces that I felt would be useful in addition to extrusion capability is to also provide various serving, stranding and braiding capabilities for special designs prototyping. Planetary stranding, contra-helical serving and torque balanced contra-stranding would require equipment design from scratch for an appropriate size system for my prototyping lab. (Most commercial machines are way too large or fast to fit in a development application.) Braiding is somewhat different as the machines are relatively small and well developed. To that end, I had acquired an older Wardwell rapid braider that had spent much of its recent life stored in a development lab and was now in need of a complete rebuilding/restoration, as the main carriage was seized from congealed grease and many parts were missing or damaged. So, as with any project of this magnitude, the first step was to research the available literature and determine what could and could not be done within the cost and needs allotted for this capability.

As it turned out, the Wardwell braider company is still very much in business and a major supplier of braiding machines worldwide. Upon contacting them, I was able to immediately download a parts listing for the machine complete with line drawings of all the parts and assemblies. After contacting a real person, (not just a computer) at Wardwell I was able to receive an electronic scan of an original manual for the machine I wanted to restore/rebuild. (When I say restore/rebuild, you can see from the picture that it was in very sorry condition and a quick fix was out of the question)

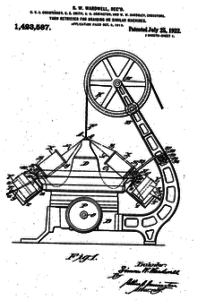

I was amazed to find that many of the illustrations in the manual were taken from the early twentieth century and that the Wardwell rapid braider was patented in 1922. Many of the parts for my braider are the same as the earliest Wardwell rapid braiders.

Pictured here is the 1922 patent drawing.

Pictured below are my braider’s critical parts, interchangeable with pre-WWII units.

The interesting part is that Aramid yarn braiding is used for many high strength and extreme use environments today such as umbilical, aerospace control cables, tether applications etc.

Since this technology originally started before the industrial revolution it seems very unique that we still today utilize many parts and machines from almost a hundred years ago. Of course, there have been many newer designs that do the same thing but faster and with even more precision than the rapid braider.

However, I can attest that there are still many Wardwell rapid braiders in use today and even several companies that specialize in rebuilding them and updating them to modern safety standards. (The original units had minimal safety guarding as was consistent with the times.)

The main capability for my use of the braiding machine is to be able to custom braid new designs for a client’s special applications.

This means the ability to modify portions of the machine for special purposes such as an unusual material to pay off or perhaps varying tensions etc. So a slower machine that is easily understood and for which parts and knowledge is readily available makes good sense for my application. Also, many clients likely have them or similar units.

The tie-in to my hobbies of restoring old machinery seems somewhat obvious except that most of that equipment is farm-related or power-related.

For example, I restore and show antique hit and miss engines, the kind that has large spoked flywheels and only fire when they slow down.

Some examples of Engines and tractors from my collection are below.

The first is a 1908 vertical 3 ½ hp air cooled and the second is a 1919 water-cooled 3 hp machine:

So once you have a few of these running you want them to run something. I.e. a water pump or winch or maybe even a sawmill and other process machines. And of course, this leads to mobile motors such as old tractors and construction equipment see below:

The first is a 1956 John Deere tracked dozer and the second is a 1952 International Harvester Cub tractor with original loader as shipped.

As you can see my progression of old iron disease, (the collecting and restoring of antique machinery to running condition) is fairly advanced. What brought my attention to this blog is that a friend in the antique engine group showed me a picture of a Wardwell braider similar to mine being put on display at an antique engine show making shoelaces and being driven by a line shaft powered by one of these flywheel engines.

I find it amazing that a machine that was new in 1922 is still being used in the development and manufacture of a product (rugged optical cable) in 2016. This reaffirms my belief that the basic processes that have stood the test of time will still be valid tools moving into the next generation. As I assemble the lab tools you will see much of the development lab process in these blogs.

Also, you will see some of my progress on the braider rebuild/restoration here as well. Who knows…. one of my old engines may be running the braider for demonstrations.

This article is an original publication of Fiber Optic Center, Inc. It is shared publicly for educational and reference purposes to support learning and professional development within the fiber optics industry.

You are welcome to read, cite, or reference this material for non-commercial and educational purposes, as long as full credit is given to Fiber Optic Center, Inc. and the author.

Reuse, reproduction, or adaptation of this content — including rewriting, republishing, or incorporating it into new materials (such as websites, blogs, marketing text, technical guides, or AI-generated content) — is not permitted without prior written consent from Fiber Optic Center, Inc.

This material is protected by copyright law upon publication, even if not formally registered.

Use of this content for AI training, automated data extraction, or derivative content generation is prohibited.

Fiber Optic Center monitors and enforces the integrity of its intellectual property through digital identifiers and content tracking.

For more details, please refer to the Fiber Optic Center Content Use and Copyright policy.