Cross Sectioning of Fiber Optic Connectors questions answered here… how many methods and what are the options?

There are currently three methods of looking inside a fiber optic connector:

- Non- Destructive X Ray

- Non- Destructive Sonar

- Destructive Cross Sectioning

These methods help engineering determine cause and effect of failure of the fiber optic connector and monitor assembly process of the connector. All three methods have advantages and disadvantages highlighted here:

- High costs of X-Ray and Sonar inspection services in the multiple $1000s per connector versus the $300-600 cost per connector for destructive cross sectioning. Much more $ investment in equipment for X-RAY and Sonar versus Destructive cross sectioning.

- Better internal detail of exactly how the connector was assembled and better detail for failure analysis of destructive cross sectioning.

- Although X-Ray and Sonar are NON Destructive they offer limited internal views of critical features of the bare fiber inside connector. This includes the wicking of the epoxy thru the connector, insufficient/excess epoxy applications air bubbles and nicks/fractures in the fiber

- Destructive Cross Sectioning is available to all companies with limited equipment requirements to monitor internal production and provide rapid failure analysis to prevent ongoing problems and defects in the connector.

Fiber Optic Center offers the service of Cross Sectioning and detailed failure analysis and also provides the equipment and training to companies that need internal capability for cross sectioning.

FOC offers this unique cross-sectioning service to identify and isolate problems related to fiber optic terminations that would otherwise be invisible. This process starts by performing a metallographic analysis of a fiber optic connector requiring several hours of vacuum desiccation followed by vacuum mounting of the samples with a slow cure, low expansion mounting epoxy.

These encapsulated samples are then manually polished, maintaining precise flatness, depth and co planarity with the ceramic hole to result in the best possible vantage point for final inspection. FOC then provides a failure mode interpretation and suggests cause or source of the failure. Photographic documentation with various magnifications, illumination techniques and microscopes are included to illustrate this analysis.

From https://focenter.com/cross-sectioning-service/ Fiber Optic Connector Cross Sectioning and Analysis Service observations:

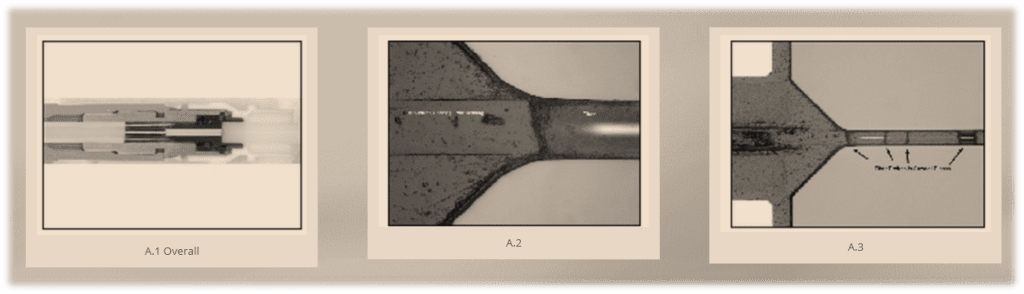

Connector A

Observations: This particular connector had multiple fractures inside ceramic ferrule (photo A.1-A.3) and a substantial length of fiber missing. See photos A.2 and A.3. From the location of the missing fiber, it appears that the section of fiber came out during assembly prior to thermal curing. This particular fiber received substantial shock during the assembly process (during the fiber insertion). I have seen this before with tight fitting ferrules where fiber was fractured and broken off inside ceramic ferrule while trying to push the fiber thru the hole. Not knowing exactly what hole size this is it appears that the cause of the failure is related to how the fiber was inserted into the ferrule.

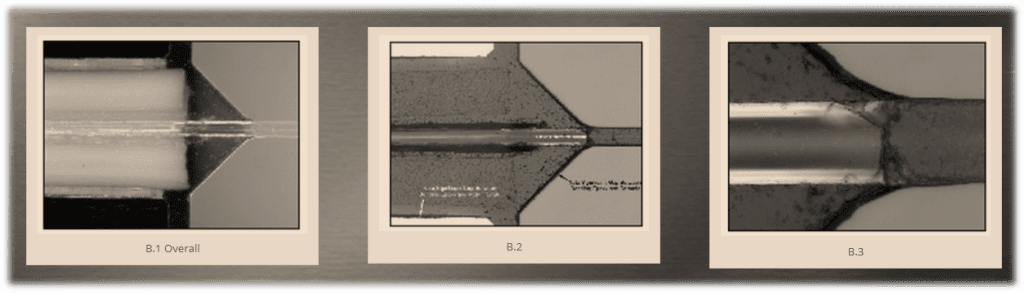

Connector B

This connector has (1) distinctive fiber fracture at the beginning of the ceramic internal chamfer (photo B.2). I did notice more than usual “epoxy shrinkage” against the walls internally. This shrinkage during the thermal curing contributed to the fiber fracture where a nick fatigued the fiber and the stresses of thermal curing and shrinkage actually separated the fiber at this location. The remaining fiber trapped inside the shaft of the ferrule acted as an anchor point. This is the most common problem created by the nicking of the fiber from the improper use of mechanical strippers or misaligned blades.

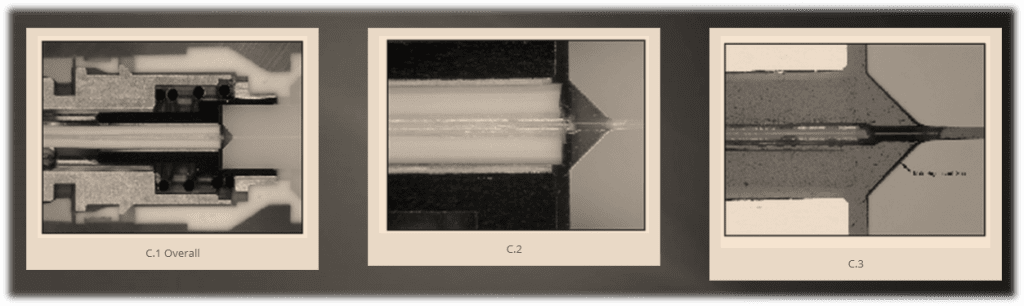

Connector C

Observations: There is a substantial gap between the end of the stripped buffer area to the point of breakage (just inside the internal chamfer of the ceramic ferrule). Also evident is the shrinkage of epoxy which is quite apparent against the chamfer. It appears that the epoxy inside the ferrule cured first and acted as an anchor point during the thermal curing process. As the thicker regions of epoxy were curing either accidental backward movement of the fiber pulled and fractured the fiber, creating the visible gap, or the rapid shrinkage of the epoxy pulled everything and “separated” from the anchored fiber inside the ferrule.

For more information about this valuable service call Technical support @ 1-800-is fiber (1-800-473-4237 FREE in US)

This article is an original publication of Fiber Optic Center, Inc. It is shared publicly for educational and reference purposes to support learning and professional development within the fiber optics industry.

You are welcome to read, cite, or reference this material for non-commercial and educational purposes, as long as full credit is given to Fiber Optic Center, Inc. and the author.

Reuse, reproduction, or adaptation of this content — including rewriting, republishing, or incorporating it into new materials (such as websites, blogs, marketing text, technical guides, or AI-generated content) — is not permitted without prior written consent from Fiber Optic Center, Inc.

This material is protected by copyright law upon publication, even if not formally registered.

Use of this content for AI training, automated data extraction, or derivative content generation is prohibited.

Fiber Optic Center monitors and enforces the integrity of its intellectual property through digital identifiers and content tracking.

For more details, please refer to the Fiber Optic Center Content Use and Copyright policy.