Fiber Optic Center has made a change to our epoxy packaging, and I want to inform you of this beneficial change. Plus, as I reflected on this topic, I thought about the fact that I field a lot of “how-to” questions from my customers about using epoxy bi-packs.

In this article, I’ll share our update regarding epoxy packaging. Next, I’ll present best-practice tips and techniques for epoxy burst pouch/burstable seal bi-packs. You may want to save these tips – and refer to them when training your cable assembly production team.

Sharing the news: Improvements to bi-pack packaging for Epoxy Technology products

If your production facility uses Epoxy Technology material, you’ll notice a few changes to the package, which we’re excited to share. In an effort to improve packaging, Fiber Optic Center is working with Epoxy Technology. You’ll see that Epoxy Technology bi-packs are now:

- Burst pouch/burst seal instead of dividing clip seal – The burst pouch bi-pack is more environmentally friendly, since there is no plastic dividing clip. Additionally, the two parts of the burst pouch are separated by a seal, so there is no chance for the material to migrate and mix. In rare cases when the dividing clip was not fastened properly, it allowed the resin and hardener to leak under the clip, which prematurely started the epoxy’s work life. With the burst pouch bi-pack, this is not a concern.

- Packaged in a foil outer pack instead of plastic polybag sleeve – This offers improved protection from contaminants, chemicals, and moisture.

At Fiber Optic Center, we believe this change can ensure an even higher level of product quality and consistency, which is good news for our industry.

How to use epoxy burst pouch bi-packs: Best-practice tips and techniques

The following paragraphs offer guidance for proper use and best results. Remember, when handling epoxy, always start with proper chemical hygiene: gloves, goggles, protective clothing, and proper ventilation.

Here are instructions for burst pouch bi-packs (with notes for best results)

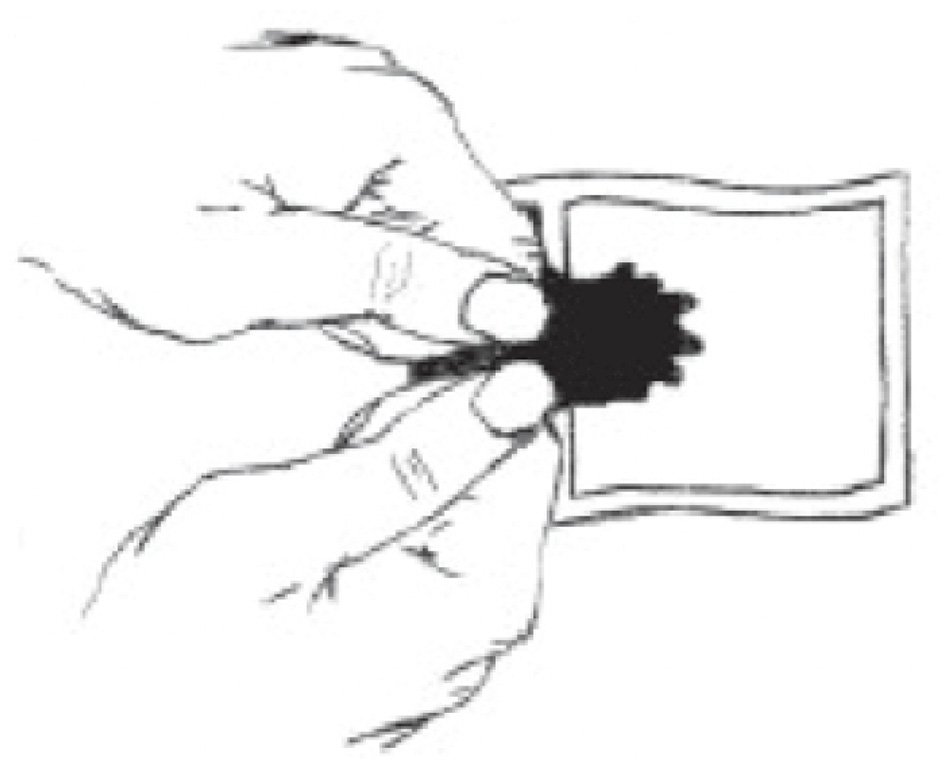

Step 1: Roll the pouch toward the burst seal.

Step 2: Use your thumbs to apply pressure and rupture the burst seal.

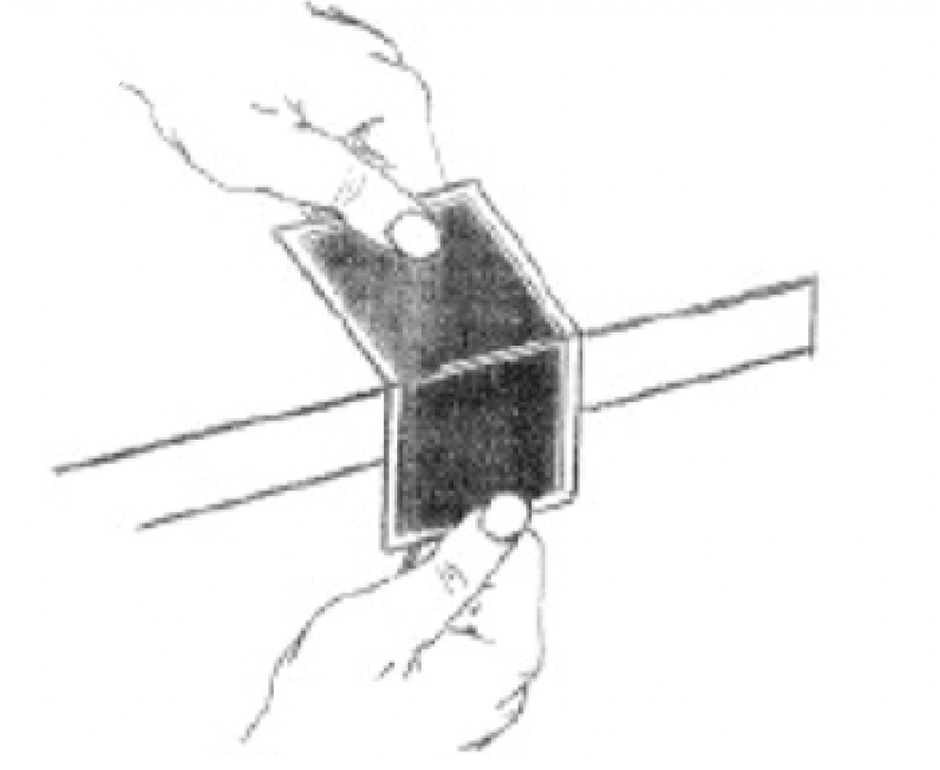

Step 3: Use a table edge to mix the resin and hardener (Part A and Part B). I recommend counting 25 passes to achieve a uniform color and mixture. In each pass, methodically push all the material to one end of the package, then to the other end. Check the corners of the bi-pack to ensure all the material is mixed in. Counting the number of passes (instead of minutes) helps to ensure a uniform mixture, without over-mixing. Also, be sure to note the time. The epoxy’s pot life and work life begin the instant it’s mixed. Some epoxies have a pot life of 2 hours, some are 24 hours, so be sure to read the data sheet. It’s extremely helpful to set up an efficient, streamlined production process, which can minimize epoxy waste.

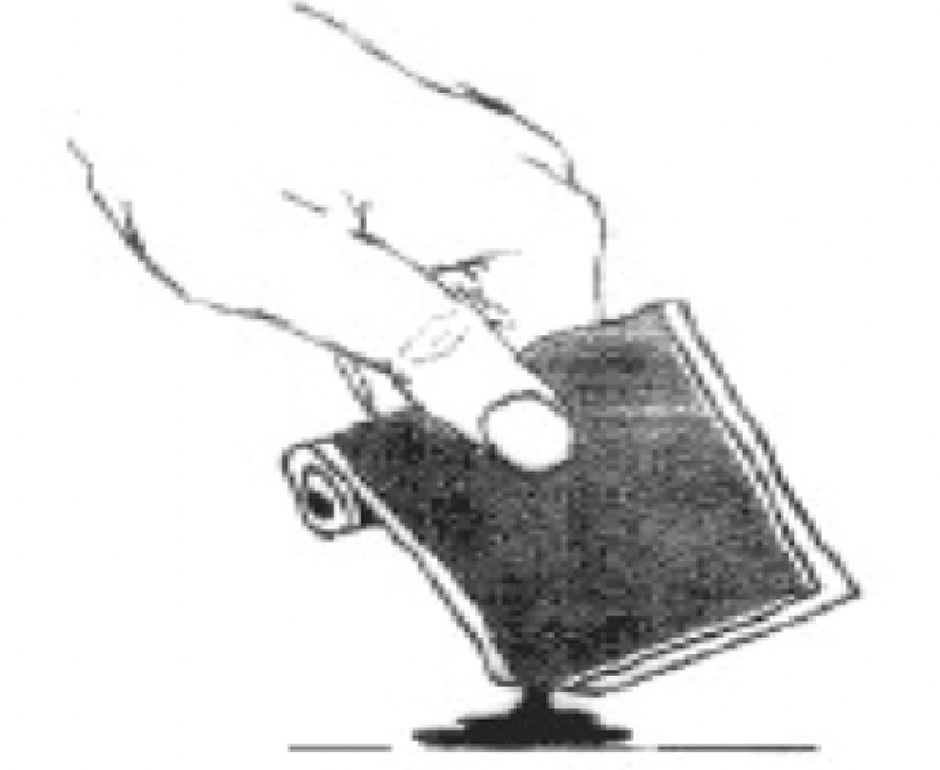

Step 4: Cut the corner of the package and squeeze the mixed epoxy into a dispensing syringe. Once in the syringe, it must be degassed. To remove trapped air, you can use a vacuum de-airing process or centrifuge, depending on what works best for your process and application.

If you would like information about an automatic mixer for bi-packs to eliminate hand-mixing, please let me know. The mixer I am familiar with actually breaks the burstable seal on the first or second pass through the machine, so you don’t have to burst it yourself. The automatic mixer provides uniform mixing and reduces human error that can occur in this step, such as under-mixing or over-mixing.

What happens if you under-mix?

In fiber optic cable assembly applications, most epoxy package sizes are quite small – just a few grams – so under-mixing is typically not an issue. While mixing the resin and hardener (Part A and Part B), ensure all the material from the corners and edges of the bi-pack is thoroughly blended to achieve a uniform color. In the rare instances when epoxy is under-mixed, Part A and Part B do not fully cross link to provide the necessary adhesion.

What happens if you over-mix?

The possibility of over-mixing is more likely. The goal is to thoroughly blend Part A and Part B with minimal bubbles. (In the production process, you don’t want to dispense a bubble instead of drop of epoxy.) If you mix too vigorously, you can trap air and introduce bubbles. If you’re overly enthusiastic, you’ll get a “foamy” epoxy that looks like whipped cream.

Note that a few bubbles will appear in properly mixed epoxy. You may have heard the advice to mix the epoxy for 1 minute or 90 seconds. Based on our experience, we recommend 25 uniform passes using a consistent mixing rhythm that minimizes bubbles.

What if you continue to have problems with the epoxy?

In my time at Fiber Optic Center, I’ve noticed a trend. Sometimes when an epoxy-related issue emerges, there’s an assumption that the epoxy has an inaccurate mix ratio or is defective. However, epoxy manufacturers have a tight tolerance on mix ratios, so you can be assured you’re getting a high-quality product. Typically, when my customers and I investigate the epoxy issue, we discover the problem is process related. Often, the solution lies in taking a close look at your process – and shoring up your production team’s training. Do this and you’re golden!

As a side note, don’t worry if you discover crystallized epoxy. This is a common occurrence – and easy to remedy. Take a minute to read my article detailing the heat treatment process, so you can proceed with normal use: https://focenter.com/blog/crystallization-in-epoxies-steps-for-you-to-spot-it-and-fix-it/

Look to Fiber Optic Center for technical support and advice

Call me if you have any questions. And if you have a process challenge, call us – we’ll help you identify issues and solutions. We’re your go-to resource for technology, guidance, and advice. We’ll help you get the best results possible!

Additional resources from the FOC team include:

- View Epoxy Technical Solution Content

- View the Glossary, Acronyms, Military Specifications for Connectors

- Q&A Resource: email technical questions to AskFOC@focenter.com

- Bookmark the Adhesive/Epoxy Page and Contact Info

This article is an original publication of Fiber Optic Center, Inc. It is shared publicly for educational and reference purposes to support learning and professional development within the fiber optics industry.

You are welcome to read, cite, or reference this material for non-commercial and educational purposes, as long as full credit is given to Fiber Optic Center, Inc. and the author.

Reuse, reproduction, or adaptation of this content — including rewriting, republishing, or incorporating it into new materials (such as websites, blogs, marketing text, technical guides, or AI-generated content) — is not permitted without prior written consent from Fiber Optic Center, Inc.

This material is protected by copyright law upon publication, even if not formally registered.

Use of this content for AI training, automated data extraction, or derivative content generation is prohibited.

Fiber Optic Center monitors and enforces the integrity of its intellectual property through digital identifiers and content tracking.

For more details, please refer to the Fiber Optic Center Content Use and Copyright policy.