As described in the article, Epoxy Dispensing Explained, there are three approaches most commonly used:

- Manual

- Pneumatic

- Volumetric displacement

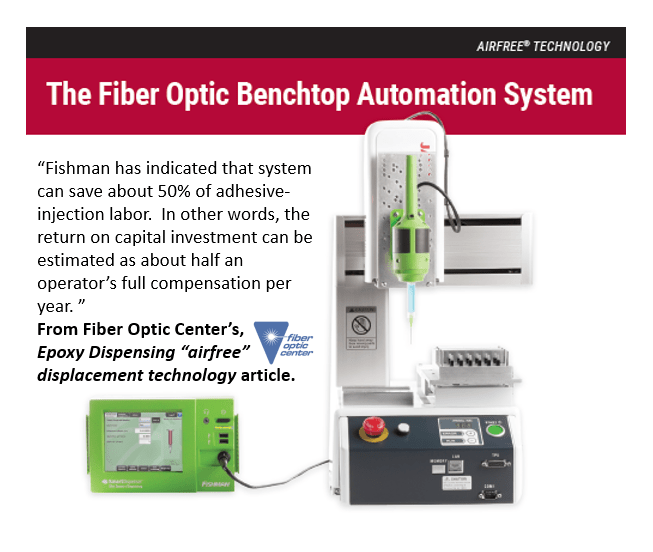

Fishman Corporation of Hopkinton, Massachusetts, USA, introduced a new automated dispensing system incorporating volumetric displacement. (Editor’s note: Fishman’s SmartAutomationTM Benchtop Fiber Optic Assembly System is available from Fiber Optic Center)

The Fishman system incorporates the company's "airfree" displacement technology, called SmartDispenserTM , which uses a stepper motor and a precision-threaded rod to operate the syringe. The robotic system also includes the company's patented connector mounts (Precision ConnectorMountTM ), a reload station, syringes, guns, accessories (racks, trays, etc.), a controller unit, the company’s automation firmware, and a robotic positioning system.

The company says that its "airfree" linear drive system uses algorithms to determine how far forward it must move into the syringe cylinder to positively displace the requested fluid amount. Reverse motion assures the proper amount of fluid is filled to the proper height inside the connector each time.” The x-y-z robotic positioning system that moves the gun is supplied by Janomie Industrial Equipment of Tokyo, Japan.

The ConnectorMount blocks are custom-made for each type of connector. The mounts have precision-machined tops to assure the dispensing tip is properly aligned. The bottoms have alignment/guide pins for positioning on the robot’s bed. A factory may use multiple blocks for each type, so that operators can load connectors into blocks while another block is running on the robot. When one block is filled, the operator can lift it off and replace it with a pre-loaded block for a quick change-over.

Fishman has indicated that system can save about 50% of adhesive-injection labor. In other words, the return on capital investment can be estimated as about half an operator’s full compensation per year. Depending on local labor rates, the ROI may be achieved in some fraction of a year. The system also offers other benefits in product uniformity, documentation, and statistical tracking that can interface with a company’s work-order and accounting software.

- For further information on epoxy dispensing, please read: Epoxy Dispensing Explained

- Visit the FOC Epoxy & Adhesives Library that includes Blog Articles, Tips and FAQs and Videos.

Errors in epoxy processes (mixing, dispensing / application, curing schedules, etc.) can lead to premature bond failures which negatively impact the reliability of any cable assembly.

This article is an original publication of Fiber Optic Center, Inc. It is shared publicly for educational and reference purposes to support learning and professional development within the fiber optics industry.

You are welcome to read, cite, or reference this material for non-commercial and educational purposes, as long as full credit is given to Fiber Optic Center, Inc. and the author.

Reuse, reproduction, or adaptation of this content — including rewriting, republishing, or incorporating it into new materials (such as websites, blogs, marketing text, technical guides, or AI-generated content) — is not permitted without prior written consent from Fiber Optic Center, Inc.

This material is protected by copyright law upon publication, even if not formally registered.

Use of this content for AI training, automated data extraction, or derivative content generation is prohibited.

Fiber Optic Center monitors and enforces the integrity of its intellectual property through digital identifiers and content tracking.

For more details, please refer to the Fiber Optic Center Content Use and Copyright policy.