Every step requires precision, starting with the core rod

This is the third in FOC's new series on doped fiber technology. The first article, "Rare Earth Doped Fibers," reviewed the main methods for making doped-fiber preforms. The second article, "Thulium-Doped Fibers," discussed the characteristics of thulium as a dopant and commented on the desire to achieve higher dopant concentrations. The article below looks in more detail at steps in making doped fiber preforms starting with halide-process MCVD core rods.

Many high-tech products are made with a sequence of procedures such that each step builds on the accuracy and precision of the preceding step. This is especially true of rare-earth doped fiber, which requires knowledge of preform fabrication, fiber draw, measurements, and basic understanding of waveguide propagation and laser fundamentals. Making the preform, for example, involves steps that require knowledge and experience in several realms: handling chemicals, managing the deposition process, understanding glass materials and their properties, and glass-working skills, such as grinding, shaping, stretching, straightening, and joining.

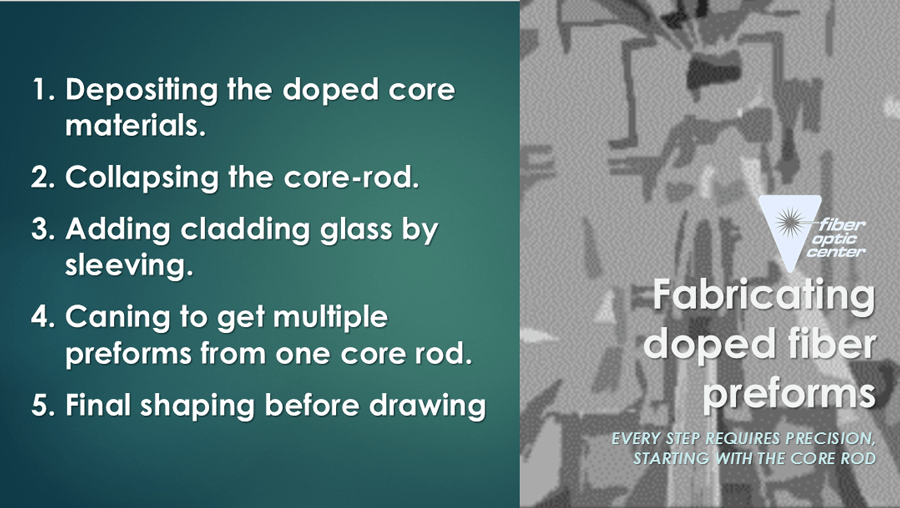

Some of the steps in making doped fiber preforms take place on machines under software control. Other parts of the process depend on the operators’ decisions and in some cases on their skill in working with hot glass; the steps involve both technology and technique. This article will walk you through the critical steps, starting with the core rod. As noted in the previous articles, we believe the halide MCVD process is particularly well suited for achieving optimal doped fiber characteristics for many applications.

Core and cladding rely on different processes

An MCVD-doped fiber preform has several layers of glass materials. The doped fiber core is deposited inside a high-purity quartz tube. This starting tube’s quartz becomes the first layer of cladding glass. Subsequent steps use sleeving tubes to increase the amount of cladding glass. For many applications, this preform is then "shaped" by grinding flats on the outer surface. This hexagonal or octagonal shaping is done to maximize the mixing of modes in the first cladding and therefore maximize absorption in the core.

The shaped preform is then drawn, polymer-coated, and proof tested. For some doped fibers, called "double-clad," the polymer coating is a low-index material that serves as a secondary cladding. The quartz material from the starting tube and sleeving tubes is the primary cladding.

Preform size and shape vary among applications

Many elements of the preform-making process are tailored to arrive at the requisite fiber geometry. The amount of core material to be deposited, the amount of cladding glass to be added, and the final shaping all can vary with the fiber’s design, which in turn is driven by the doped-fiber application. Erbium-doped fibers for telecom amplifiers, for example, have the same outside diameter and similar core-cladding ratios as telecom transmission fibers.

Doped fibers for lasers and sensors, on the other hand, may have significantly different core and cladding diameters, numerical apertures, and cladding shapes. These variables are driven by such factors as the type of pumping, amount of absorption and gain, temperature, modal qualities, wavelength of operation, and many other operating characteristics. Some fiber lasers, for example, use doped fibers with a 20-µm core and 400-µm cladding. For fibers with an octagonal primary cladding, the 400-µm diameter measurement is the diagonal from one vertex to another.

MCVD deposition and sleeving tubes are the building blocks

- Depositing the doped core materials. Most fiber makers procure starting tubes from outside sources. There are several companies that specialize in high-purity quartz substrates, rods, tubes, and other shapes for fiber manufacturers. A typical size for the deposition tube is 25-mm outside diameter and 1-meter length. Other sizes are available. For custom sizes, the tube manufacturer’s process may mean the customer has to buy a larger quantity.A typical specification for wall thickness is 3 mm, or a 19-mm inside diameter. The fiber maker may specify alternative sizes depending on the amount of core material to be deposited and the planned geometric characteristics. The doped core material is deposited on the tube’s inner wall in thicknesses that are on the order of 100 µm (or several hundred microns).

- Collapsing the core-rod. The deposition results in a hollow cylinder with the doped material on the inner wall. This must be collapsed to form a solid rod, with a solid doped core. The goal is to get a straight rod with good core-cladding concentricity, geometric consistency, and no contaminants – no moisture (low OH- ). This step is done on the preform lathe, while the rod is hot and turning. The deposition temperature typically is 1800 to 1900° C. During collapse, the temperature is several hundred degrees higher, and the burner passes along the rod at a slower rate. The gas pressure inside the tube is carefully controlled along with the burner passes. This is done to maintain a good balance with the surface tension forces, thereby assuring that the tube collapses with a uniform cylindrical shape. At this point, the collapsed rod is almost ready for sleeving, which will build up the cladding material. After collapsing, the core-rod may not be straight. In such a case, the core rod must be straightened so it can be inserted into a straight sleeving tube. This is where some glass-working craftsmanship comes in. This process is done on the lathe, again with heat, and the operator uses hand tools to manually straighten the rod. Then, the last steps before the sleeving operation are to clean and fire-polish the rod.

- Adding cladding glass by sleeving. An integral part of all these preform steps is careful inspection, measurement, and testing of mechanical, geometric, and optical characteristics. For example, the collapsed core rod’s precise dimensions are necessary for planning the sleeving steps to achieve the desired fiber core diameter and core-clad ratio. A commonly used sleeving tube size has a 32-mm outside diameter, 20.5-mm inside diameter, and 1-meter length. Different diameters and wall thicknesses are available, but the preform maker’s options may be limited by the size of the burners and other lathe parameters. Depending on the core-rod and sleeving tube dimensions, it may be necessary to stretch the preform before it will fit inside the tube.Stretching can be done on a lathe fitted with a movable tailstock, but this process is limited by the lathe’s length and sagging due to gravity. An alternative is vertical stretching on a tower like a draw tower. This allows greater lengths and better geometric control. In either case, the heat and stretching movement are carefully controlled.The process of collapsing the sleeving tube onto the core rod also can be done on a horizontal lathe with a moving burner or on vertical equipment with a burner or furnace, again with careful temperature and motion control. After collapsing the sleeving tube, the result is a solid glass rod. Depending on the plan and the desired dimensions, it may be a preform ready for drawing or an interim unit that will get more sleeving tubes.

- Caning to get multiple preforms from one core rod. In many cases, the geometric targets are achieved by stretching or "caning" that interim unit, cutting it into shorter lengths, and collapsing sleeving tubes onto each of those. In some case, a rod with one sleeving tube may be stretched to lengths on the order of 10 meters and cut into multiple segments. For such lengths, the stretching process is done on a vertical tower, using a process speed that is much slower than that used to draw fiber. There are different procedures for "cutting" the longer rod into segments. The choice depends on the core dopants, the geometry, and other glass characteristics. The options involve different temperatures and mechanical processes. Thus, sleeving can involve many complex steps, yielding four or more preforms from one MCVD-deposited core rod. Again, all of this requires precise measurements, careful handling, and cleaning.

- Final shaping before drawing. Some preforms may be drawn after the previous step, with a round cross section. For some fiber laser applications, however, a shaped preform – say hexagonal or octagonal – is preferred to achieve better mixing of pump-laser output modes in the core. Why is this shaping advantageous? In a cylindrical fiber with a concentric core, the pump energy can propagate in the cladding, totally missing the doped core.

Over the years, different geometries have been developed to improve pump power absorption. One strategy is to grind one or more flats on the preform's outer edge. This must be done carefully to minimize surface flaws, which could cause problems during drawing and coating. Then the drawing temperature must be optimized to avoid rounding off the desired shape. Along with the temperature, the draw speed and tension must be controlled to achieve the right fiber diameter and strength. (As with making preforms, the drawing process for rare-earth doped fiber has many variables and complexities. Draw-related topics will be covered in future articles in this series.)

Conclusions:

We've shown there is a sequence of steps – deposition, collapsing, sleeving, caning, cutting, re-sleeving, and final shaping – to get from the starting tube to a preform that's ready for drawing. Each step includes careful measurement and testing. And there are yield factors at each step. For example, some of the glass at the ends of the core-rod and tubes is lost at each stage. And the testing processes may further reduce the total amount of deposited or sleeved glass to be drawn. With these various yield factors, the success of each step depends on the success of the preceding steps. Thus, it is critical that the process start with good core rods. For many of the rare-earth dopants and the desired fiber characteristics, such as index profile, NA, etc., the halide process can be instrumental in getting good core rods.

The amount of fiber drawn from one preform depends on fiber diameter, drawing yield factors, and other variables. In general terms, a one-meter rare-earth doped fiber preform may yield in the range of one to five kilometers of fiber. Thus, if one core rod can yield four or more preforms, it can yield on the order of 10 km of fiber. Or, depending on the amount of fiber specified in a laser or amplifier’s gain medium, one core rod can provide enough fiber for hundreds of lasers or amplifiers.

Getting to this level of output involves careful measurements, machine set-up, process control, and sometimes even craftsmanship at each step. FOC has the experience to help with all steps in the process. Please contact us for assistance with questions concerning any step, from planning your process to outgoing inspection.

This article is an original publication of Fiber Optic Center, Inc. It is shared publicly for educational and reference purposes to support learning and professional development within the fiber optics industry.

You are welcome to read, cite, or reference this material for non-commercial and educational purposes, as long as full credit is given to Fiber Optic Center, Inc. and the author.

Reuse, reproduction, or adaptation of this content — including rewriting, republishing, or incorporating it into new materials (such as websites, blogs, marketing text, technical guides, or AI-generated content) — is not permitted without prior written consent from Fiber Optic Center, Inc.

This material is protected by copyright law upon publication, even if not formally registered.

Use of this content for AI training, automated data extraction, or derivative content generation is prohibited.

Fiber Optic Center monitors and enforces the integrity of its intellectual property through digital identifiers and content tracking.

For more details, please refer to the Fiber Optic Center Content Use and Copyright policy.