FC Connectors, also known as Ferrule Core Connectors, are often referred to by various names like "Fiber Channel" or "Frank Charlie" in the industry. Developed by NTT (Nippon Telegraph and Telephone) in the late 1970s as the "Field-Assembly Connector," FC Connectors were the first to feature a ceramic ferrule. They are compatible with other connector types like SC and ST, typically featuring stainless steel or plastic bodies. Their screw-design and alignment key make them ideal for single-mode fibers.

The FC Connector pioneered low loss (below 0.5dB) for single-mode fibers without active alignment by utilizing a floating split sleeve in the adapter. This innovation, along with the transition to all-ceramic ferrules, significantly improved connection quality. Enhancements like index matching gel and anti-reflective coatings were once common but became unnecessary with the advent of PC Ferrules, which have radiused end-faces.

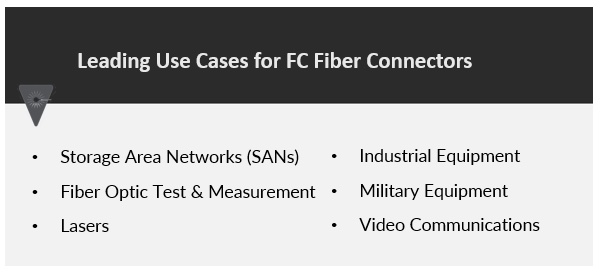

Despite their historical prevalence, FC Connectors are less favored in modern networks due to the cumbersome screw mechanism, which is less suitable for high-density applications. They've largely been supplanted by easier-to-use LC and SC Connectors, although they retain a 2.5 mm ferrule like ST and SC. The threaded design, however, ensures a secure, high-quality connection, making them suitable for high-speed storage area networks (SANs).

FC Connectors are particularly effective in environments requiring consistent data transmission, such as video streaming, where maintaining connection integrity is crucial. They are also used in measurement equipment and single-mode lasers, providing reliable connections in field applications like OTDRs. Their durability makes them well-suited for harsh conditions in industrial or maritime settings.

Key features of FC Connectors include:

- Durability for frequent connections/disconnections

- Support for high-speed data transmission (up to 64 Gbps)

- Stable, secure connections via threaded design

- Cost-effectiveness compared to other connectors

The FC/PC (Physical Contact) and FC/APC (Angled Physical Contact) connectors are standardized under TIA EIA/TIA-604-4 and IEC 61754-13. For APC connectors, understanding the difference between step and conical ferrules is crucial for proper polishing. FC/APC Connectors come with different key widths tailored to specific loss requirements.

Assembly of the FC Connector requires specific equipment and processes. Fiber Optic Center is the industry leader for recommended FC Connector materials and equipment designed specifically for FC assemblies. Integrating our manufacturing knowledge into our customers’ worldwide operations begins with the best practices and selections.

This article is an original publication of Fiber Optic Center, Inc. It is shared publicly for educational and reference purposes to support learning and professional development within the fiber optics industry.

You are welcome to read, cite, or reference this material for non-commercial and educational purposes, as long as full credit is given to Fiber Optic Center, Inc. and the author.

Reuse, reproduction, or adaptation of this content — including rewriting, republishing, or incorporating it into new materials (such as websites, blogs, marketing text, technical guides, or AI-generated content) — is not permitted without prior written consent from Fiber Optic Center, Inc.

This material is protected by copyright law upon publication, even if not formally registered.

Use of this content for AI training, automated data extraction, or derivative content generation is prohibited.

Fiber Optic Center monitors and enforces the integrity of its intellectual property through digital identifiers and content tracking.

For more details, please refer to the Fiber Optic Center Content Use and Copyright policy.