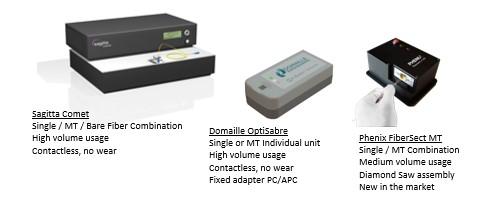

With the introduction of mechanical MT cleaving by Phenix FO at OFC 2015 along with the existing laser cleaving options already on the market from Sagitta and Domaille we thought it might a good idea to line them up next to one another and compare the differences.

Prior to the advent of these systems, the industry was using either a manual scribe or some proprietary solution to remove the excess fiber. The next step is a manual airpolish / denubbing to remove the sharp edges before the epoxy can be polished off. With MT termination there is an even more manual process needed to remove the excess fiber and epoxy bead.

In addition to the need for semi-automated process jobs that increase production yields and performance, the volume increase over the last years requires lower produced cost hence that the emphasis is high at high-value MT termination assembly processes.

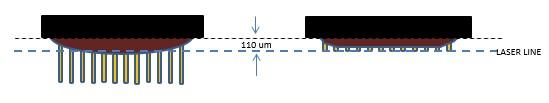

Sagitta introduced the first generation Comet laser cleavers in 2006 and created a platform addressing bare fiber (single & ribbon), single ferrule (single & multimode as well as large core 220/1000nm fibers), and multi-fiber ferrule (MT) to be cleaved with a single CO2 laser beam at approx. 60-200um above the ferrule tip.

Do low-profile cleavers reduce lapping film, right or wrong?

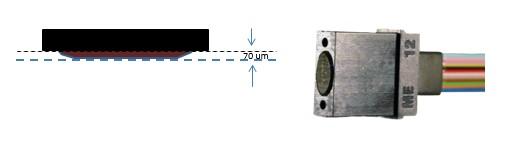

The latest generation of single fiber cleaving comes in the Comet SSP. It uses a bi-directional laser beam which allows for ultra-low profile cleaves at 30-35um above the ferrule tip, reshaping the fiber and removing almost all epoxy. By selecting single fiber pre-domed connectors, this laser cleaver allows cleaved connectors to be taken straight to a single final polish step when using a stable high-quality polisher. In production, however, we have found a 3um silicon carbide ‘half’ step is needed to help clean the ferrule before the final step. This means the removal of all diamond film polishing steps and thus will result in a significant cost reduction on polishing material while also improving capacity and yield.

SMA connector application

Laser cleaving shows also a significant process advantage for large-core fiber applications with SMA connectors terminated as the laser beam cuts thicker fibers which are more difficult to scribe.

SMA High Power application

For high power connectivity, where epoxy-less free-standing SMA’s is used, most companies use supportive wax-like CrystalBond in the SMA connector to prevent the fiber from breaking during polishing while it needs to be removed afterward which is a time consuming costly operation. Using a laser cleaving operation eliminates the need of using the supportive wax as the fiber protrudes very little from the SMA tip allowing directly a polishing operation when a high stability polisher like Domaille Engineering is used. The time reduction is significant while the less lapping film is consumed.

Fiber Bundle application

Another application that noticed a great advantage of using the laser cleaver is fiber bundles. As multiple large fibers and a significant amount of epoxy force the manual cleave to be far from the ferrule tip, the laser cleaver will “cut” in multiple scans from multi directions the excess fiber in a single operation and provide a flat finish for automated polishing.

Ribbon Fiber application

With regards to ribbon fiber technology such as MT ferrules, a laser cleaver offers a nice even scan providing a uniform fiber height over all fibers. A traditional manual operation shows often either a dome scribe just above the epoxy beat or a straight scribe with sharp fibers. A careful manual de-nubbing of the fibers is highly appreciated before polishing to avoid fiber breakage into the epoxy zone.

An additional advantage with ribbon fiber cleaving is that the epoxy beat is largely removed but keeps all fibers embedded and protected. The epoxy plateau creates a larger surface minimizing the potential fiber breakage on outer fibers and shows also a more uniform fiber protrusion after polishing, measured as the differential fiber height with the interferometer.

Laser vs Mechanical cleaving

Managing a precise material to cut through fibers with a significant amount of epoxy and repeat this for 100.000’s cleaves is a challenge. With the introduction of the Fibersect from Phenix FO we learned its cuts are very consistent and repeatable with a very low profile cut. Somewhere around 70um from the ferrule tip which is lower than standard laser cleavers, but not the Comet-Ssp. The fibers are completely embedded and protected during the initial polishing stage. Although the fiber surface is much rougher than laser cleave profiles, it doesn’t seem a disadvantage as polishing needs to be done. The lower cost is another advantage over laser cleaving systems.

Is Laser cleaving suitable for every assembly operation?

The investment for cleaving systems is still significant and a semi-automated process might look attractive but the financial numbers need to reflect the improvements. An initial comparison between the manual cleaving operation and the laser cleaving operation is often concentrated on the time of cleaving. As the operation time of a manual cleave is a matter of seconds, the manual cleave operation itself is in its advantage. Although the capacity of this operation is usually not a process bottleneck it’s evident that a laser cleaver shows its advantage with low profile cleave when reduced polishing costs on single fibers are taken into account. Generally, volumes above 200.000-300.000 terminations per month (depending on the type of termination) start to show the break-off to consider this type of automation. For the MT cleaving process, the volume required to justify is much lower as the installed cost of an MT ferrule is much higher.

Having a further look in the process like de-nubbing, epoxy removal, and related rework (due to inconsistency prior to polishing) the comparison becomes interesting. Fiber Optic Center installs over 10 years of laser cleavers globally and is probably a great source to get in contact with to understand the benefits and cost and quality improvement that a cable assembly operation can achieve.

Please feel free to contact us through AskFOC@focenter.com or at www.focenter.com

Resources

Fiber Optic Center is a resource for questions on this and all technical subjects. AskFOC can be found at: https://focenter.com/askfoc/ and the Fiber Optic Center technical experts will answer your questions here.

This article is an original publication of Fiber Optic Center, Inc. It is shared publicly for educational and reference purposes to support learning and professional development within the fiber optics industry.

You are welcome to read, cite, or reference this material for non-commercial and educational purposes, as long as full credit is given to Fiber Optic Center, Inc. and the author.

Reuse, reproduction, or adaptation of this content — including rewriting, republishing, or incorporating it into new materials (such as websites, blogs, marketing text, technical guides, or AI-generated content) — is not permitted without prior written consent from Fiber Optic Center, Inc.

This material is protected by copyright law upon publication, even if not formally registered.

Use of this content for AI training, automated data extraction, or derivative content generation is prohibited.

Fiber Optic Center monitors and enforces the integrity of its intellectual property through digital identifiers and content tracking.

For more details, please refer to the Fiber Optic Center Content Use and Copyright policy.