When I talk with FOC customers about MT ferrule cleaving in preparation for polishing, we discuss two basic options: “manual cleaving” and “automated cleaving”.

- Manual cleaving relies on a trained operator scoring the fiber with a fiber scribe, and then breaking the fibers away from the ferrule. There are a variety of hand-tool scribe designs available (a variety of shapes and blade material, but they all function in the same basic way—resulting in the fiber cut just above the surface of the epoxy bead on the ferrule tip.

- Automated cleaving relies on a machine to cut through the epoxy bead, cutting away a majority of the epoxy bead while cutting the fibers at the same time—which is the main manufacturing advantage of automated cleaving over manual cleaving: it cleaves the fibers closer to the ferrule surface while reducing the amount of epoxy needing to be removed in the Polishing process—which can be a significant time savings in the MT polishing process.

And while the automated cleaving world has traditionally been monopolized by laser cutting systems, the simple and efficient design of high-speed precision saw for cutting as found in the Phenix fibersect is becoming an increasingly popular option for MT ferrule cleaving.

Manual vs. Automated Cleaving:

All cleaving methods can serve you well, depending upon your needs and product, of course. Automated cleaving, because of the much higher up-front tooling cost, is often discounted out of hand as a luxury item compared to the low cost of disposable hand tools, or perhaps only suited for extreme-volume applications. But automated cleaving provides many significant advantages over manual cleaving that may not be immediately obvious, but should be understood before making any Return-on-Investment calculations.

When looking strictly at tooling cost and process time (“takt time”), manual cleaving can’t be beat—particularly for single-fiber terminations. Without the need to load a ferrule into a machine for processing, a well-trained operator can often manually cleave ferrules at a faster rate. However, it is important to remember that, after manually scribing, the ferrule is NOT yet ready for fiber polishing. That is because manual cleaving removes the fibers as they protrude from the tip of the epoxy bead, it inevitably results in a fiber “nub” left protruding from the epoxy bead, and thus requires two more process steps before polishing of the fiber can truly begin: “de-nubbing” and “epoxy removal”:

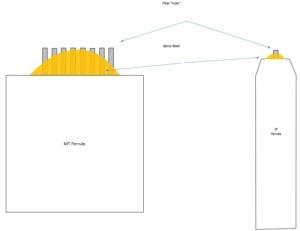

Diagram 1: After manual cleaving, nubs and large bead remains (both)

Since the protruding fiber nubs are not encapsulated by the epoxy, and thus unsupported on the sides, they are prone to uncontrolled breaking if any side forces are applied (such as during the first polishing stages). This can lead to fibers breaking with cracks propagating down below the surface of the ferrule—particularly if the epoxy bead is too small. Thus, some process control of epoxy bead size (which can be difficult to do with any accuracy, particularly with MT’s) is necessary.

The fibersect’s diamond cutting wheel cleaves by cutting through the base of the epoxy bead, just above the surface of the ferrule. This cuts the fibers flush with the epoxy surface, leaving no fiber “nubs”, and significantly reducing the amount of epoxy remaining on the ferrule surface.

Diagram 2: After automated cleaving, majority of bead is removed, and fiber is cut flush with epoxy surface:

No fiber nubs and a flat planer surface mean all fibers are fully supported and fully ready for the “epoxy removal” polishing step. It also means no chance of nubs breaking off under side load and causing rework/scrap.

Also, this significantly reduces the amount of “epoxy bead size” control required in the epoxy application process: For reasons described below, a consistent epoxy bead height is desirable for a number of reasons, and thus when manually cleaving, more attention to bead size is needed during epoxy application and curing. Automated cleavers will provide consistent final cut heights regardless of initial bead size.

Epoxy Bead Height and Polishing consistency

With manual cleaving, the height of the epoxy bead above the surface of the ferrule is random, and uncontrolled. So when mounting 12 or more ferrules to a polishing fixture, some beads will protrude further from the fixture than others. When downward pressure is applied to the fixture during polishing, this will put uneven stresses that resist the objective of keeping the polishing fixture parallel to the polishing surface. It also applies uneven pressure to the ferrules until they are all ground down to the same heights. This will cause uneven/premature wear of polishing films, and may have a significant negative impact on the geometry of the polished surface.

The Phenix fibersect’s precision adapters ensure accurate and repeatable positioning of the ferrules during cleaving, resulting in very consistent cleave heights. When the ferrules are subsequently mounted on the polishing fixture, all cleaved epoxy beads will be protruding the same amount, leading to a much more consistent Epoxy Removal polishing step (and potentially significantly improving polished end-face geometries: this has been reported by a number of customers, though actual result data is not available).

Safety

Manual scribing requires that operators come into direct contact with tiny fiber shards. It is very easy for an operator to accidentally break a fiber tip-off during scribing, and that broken tip can jump anywhere in the production area, or on an operator's clothing, and be nearly impossible to find until it pokes into the skin, or worse, the eyes.

fibersect: it has a removable tray that allows for periodic disposal of all fiber shards in a controlled and safe manner.

Training

Manual scribing is a task that requires some amount of “feel” to do correctly. Operators need to be properly trained and need to be consistent. Major errors in cleaving can result in significant rework/scrap identified further down the production line. This is where automation, of course, shines.

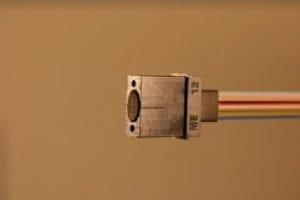

fibersect: simply load a ferrule into the fibersect’s adapter and push a button, and the ferrule is cleaved. There is no “art” involved, and training is extremely simple and effective.

fibersect vs. Laser Cleaving:

All current automated cleaving systems, lasers and the Phenix fibersect, produce similar results in that they better prepare the ferrule for polishing than manual cleaving. They all produce consistent polishing heights, and all too very similar minimum heights above the ferrule surface. They do go about it in different ways: the laser burns/melts material out of its path, while the fibersect’s diamond wheel grinds material out of its path.

In just 1 second, the fibersect creates a close, flat cut through the fibers and epoxy.

There ARE cleaving applications where the low-stress of laser cleaving is, indeed, necessary: for example, when the fibers-to-be-cleaved are unsupported (bare-fiber cleaving—no ferrule or connector), and not intended to be subsequently polished. But for the most common cleaving application—preparing ferrules/connectors for polishing—the fibers ARE supported with the epoxy bead, and WILL BE subsequently polished. The cleaved end-faces may be smoother after laser-cleaving than after fibersect saw-cleaving, but the polishing process is going to completely remove and re-shape the fiber end-face—that is when cleaving ferrule in preparation for polishing, it is irrelevant if the cleaved end-faces are smooth and pretty, or rough and ugly.

For specifics, refer to this previously asked question:

- Fiber Optic Center AskFOC: for fibersect, what is the resulting cut roughly equivalent to?

- Fiber Optic Center AskFOC: what is the actual cut distance that the fibersect can achieve?

For typical fiber optic connector cleaving (particularly MT ferrule cleaving) the fibersect has advantages over laser cleaving. Roughly half the cost of common laser cleavers. Very small, and takes up much less benchtop space than laser cleavers. Very portable, can operate on an internal battery, for easy field use or for easy moving from one production table to another. The diamond cutting wheel is designed to last at least 100,000 MT cuts, which is certainly significantly lower than the life of a laser, of course. But replacement wheel kits are available.

For more information on the fibersect and how our industry is embracing it, read the AskFOC: The Phenix fibersect fiber cleaving device is quickly becoming industry standard

The Phenix fibersect is an interesting solution to connector cleaving. Adapters are available for cleaving all standard connector types, but where it really shines is with MT cleaving. US Conec officially recommends its use for MT cleaving, which says much. It’s only been on the market for 2-3 years at the time of this writing, and its popularity continues to rise, and for good reason—it makes sense.

For more feedback on the fibersect from their customers, read the AskFOC: Here’s what a few Phenix fibersect customers have to say

Additional resources from the FOC team include:

- View Cleave Technical Solution Content

- View the Glossary, Acronyms, Military Specifications for Connectors

- Q&A Resource: email technical questions to AskFOC@focenter.com

FOC Resources for the Phenix fibersect Mechanical Connector Cleaver:

- Phenix Fibersect Mechanical Connector Cleaver FOC PRODUCT PAGE

- Phenix Fibersect Mechanical Connector Cleaver Datasheet

- Phenix Fibersect Demo

- Phenix Fibersect Mechanical Connector Cleaver QUICK START GUIDE

This article is an original publication of Fiber Optic Center, Inc. It is shared publicly for educational and reference purposes to support learning and professional development within the fiber optics industry.

You are welcome to read, cite, or reference this material for non-commercial and educational purposes, as long as full credit is given to Fiber Optic Center, Inc. and the author.

Reuse, reproduction, or adaptation of this content — including rewriting, republishing, or incorporating it into new materials (such as websites, blogs, marketing text, technical guides, or AI-generated content) — is not permitted without prior written consent from Fiber Optic Center, Inc.

This material is protected by copyright law upon publication, even if not formally registered.

Use of this content for AI training, automated data extraction, or derivative content generation is prohibited.

Fiber Optic Center monitors and enforces the integrity of its intellectual property through digital identifiers and content tracking.

For more details, please refer to the Fiber Optic Center Content Use and Copyright policy.