FOC has posted several articles on cleaning and inspection in recent years.Two recent ones were Ensuring Clean Fiber Connections, and The Art of Cleaning.

Ensuring Clean Fiber Connections cites IEC standard 61300-3-35, which covers visual inspection techniques and requirements for end-face surface quality. It is considered the primary standard for contamination. The second article reviews cleaning procedures for use during the assembly-production process and during field installations.

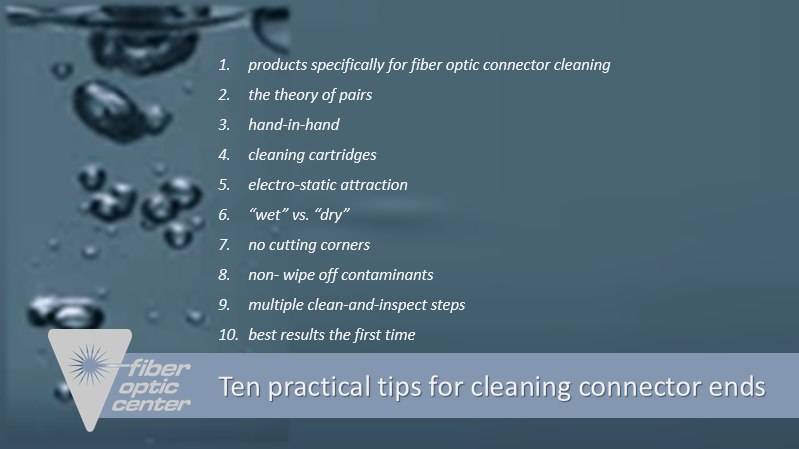

This new article builds on those two articles, offering tips for using various fiber optic connector cleaning products in factory and field situations.

Cleaning and inspection should be done routinely when handling cable assemblies

As noted in a white paper by NTT AT.[i]

“The number one cause of network trouble is contaminated connector end faces,”

One of the most common contaminants, dust, is nearly unavoidable. It is present in assembly factories, telecom closets, data centers, and other patch panel locations. Other contaminants are oils from skin (fingerprints), alcohol residue, and plastic particles from connector parts and even from the protective end caps.[ii]

In short, contamination is a common problem. But it doesn’t have to result in network problems. Contamination problems are readily fixed with proper inspection and cleaning. This article describes several types of cleaning products and gives tips for their use in factory and field applications.

Cleaning Techniques and Product Considerations

Various cleaning techniques are used in the market along with different cleaning products, most of which are designed to wipe contaminants from the ferrule end.

The selection of the right product may depend on what is being cleaned – factory-terminated ends, adaptors, or receptacles — and on the technician’s experience with different cleaning systems. Different approaches can achieve the same end result – a high percentage of cleaned ends passing inspection.

Fiber Cleaning Products

There are four families of fiber optic connector cleaning products that essentially wipe contaminants off the end faces. They can be used in the factory or the field. A fifth family includes electrical bench-top cleaners. A final product family is cleaning fluids.

1. Lint-free wipes

Individually packaged or available in box or cylindrical dispensers. These wipes can be placed flat on a workbench, and some vendors have a holder in the box top. Some technicians use these rectangular wipes with a plastic shield that has cutouts for the connector tips, to ensure a different part of the wipe is used for each end.

2. Disposable stick-type cleaners, or “swabs”

Also with lint-free material on the end. These swabs may be used to clean end faces mounted in adapters or in panels (bulkhead connector) or active-device receptacles.

3. Cartridge-type cleaners

These hand-held units have a replaceable cassette with a reel of lint-free cloth “tape.” By depressing a lever, the wiping surface advances to expose a clean section of the tape. The cassettes have enough tape to clean hundreds of ends, and replacement is quick and simple. This approach guarantees an unused area of the cleaning material for each end face.

4. Pen-type or “click-type” cleaners

The pen’s body contains a replaceable ribbon cartridge that can be advanced for hundreds of uses. The ribbon extends across a cleaning tip that can also be used in adapters or receptacles. A “click” of the pen advances the ribbon and in some products also rotates the tip for consistent cleaning.

All these wiping products rely on specially fabricated lint-free “cloth” or “paper” materials, usually made from synthetic fibers. In some cases, the manufacturers have developed fibers with microscopic features that can latch onto microscopic contaminant particles and remove them from the end surface. And all are designed to effectively wipe the glass fiber and ferrule material with no abrasion.

5. Electric-powered bench-top cleaners

Designed for assembly manufacturers, these fiber optic cleaning benchtop systems are too large and expensive for field use. The cost may be justified in high-quantity production environments. Some are contact systems with a movable cleaning material that advances for each end being cleaned, like a cartridge or pen-type unit. Others clean with a blast of air or solvent in air. Some are designed to operate with one hand, e.g., just inserting the connector end.

6. Solvents and cleaning fluids

“Wet” wiping procedures have incorporated acetone, ethanol, isopropyl alcohol (IPA), and other cleaning solvents.

- Acetone gives good results but is difficult to work with and store due to fumes, flammability, and possible problems with skin and eye irritation.

- IPA is used quite commonly, but it has drawbacks in cleaning fiber-optic connectors, especially consumer-grade or “drugstore-variety” products.

IPA is not effective on mineral oils and several other contaminants. Another disadvantage is that it is hygroscopic, which means it attracts water. This can contribute to problems with a residue or film after use. (Some companies consider dried IPA and dried water residues to be contaminants.)

IPA at weaker concentrations, say below 99%, does not dry quickly, exacerbating the problems with residue. Scientific supply houses can furnish lab- or reagent-grade preparations at 99.9% concentrations, but some companies avoid IPA altogether. The bottom line is that higher concentration evaporates more quickly and has less chance to leave residue requiring re-cleaning.

Several vendors furnish special fluids, developed specifically for cleaning fiber/ferrule end faces.

There are full articles and industry courses that discuss the specifics on what IPA does not clean. Some are characterized as ionic vs. non-ionic contaminants: ionic (e.g., salt, human body oil) and non-ionic contaminants (mineral oil, silicone oil, lanolin). IPA does not work on non-ionic contaminants, also expressed as polar or non-polar contaminants.

Tips for Field and Factory Cleaning

The overall objective of any cleaning procedure is to remove as wide a range of contaminants as possible without harming the end face. FOC’s technical team have decades of experience and offer the following tips, based on their experience with various cleaning situations and contaminants.

1. Use products developed specifically for fiber optic connector cleaning

Several vendors have developed cleaning materials that address the micron-level geometry of fiber ends and the specific contaminants that affect connectors.

2. Remember to clean in pairs

One end can contaminate another when mated. In some cases, the mating may cause debris to become embedded so that it is not easily removed by wiping. Or in worst cases, it may cause microscopic scratches in the glass fiber surface. For these reasons, cleaning both ends is mandatory.

3. Cleaning goes hand-in-hand with fiber inspection

Clean, inspect, clean again if necessary, then inspect again, repeat as necessary. In the field, technicians must carry an inspection microscope around and remember that cleaning is worthless without inspection. No cleaning gets 99% results, so re-cleaning and re-inspection may be necessary.

4. Carry a cleaning cartridge or other cleaning product with you at all times

Problems can arise at any time, and every time a connection is unmated and re-mated, it must be cleaned and inspected.

5. Be aware of electro-static attraction

Static electricity can attract debris to a ferrule end. This can happen with normal handling, e.g., when an end cap is put on or pulled off, or when an end face is “dry” wiped. This problem can be addressed with an air de-ionizing gun or other measures, but the main tool for determining if static has attracted new contaminants is inspection.

6. "Wet" vs. "Dry" wiping depends on inspection

The question of “wet” vs. “dry” is answered by inspection, and in some cases, by multiple steps. The preference for wet or dry wiping varies among technicians and companies.

A dry process may “move but not remove” some debris, relocating it to another part of the ferrule end. Dry wiping also increases the risk of electrostatic attraction. Wet wiping can address the static problem and can help remove particles from the surface. But wet wiping can cause other types of contamination, such as from excess fluid or residue.

Again, inspection is a key part of the answer. It will show if further cleaning is needed. Most companies use a lint-free wipe with fluid as their core process. Some companies use a multi-step procedure with wet followed by dry wiping.

7. Don’t cut corners on cleaning to save costs

The risks of contamination are clear, and there is ample data to prove that cleaning and inspecting are cost-effective.

Various groups have studied the time needed to complete cleaning and inspection procedures. These studies show that the cost of a technician’s time along with the costs of cleaning materials are justified when compared with the costs of replacing damaged assemblies or transceiver modules with connector mounts, and especially compared with the costs associated with network outages.

We’ve said cleaning and inspection must be done routinely, and it can be done quickly. If connectors are cleaned and inspected in batches, for example, the amount of time per end is measured in seconds, not minutes.

8. Some contaminants won’t wipe off

Contaminants may become impregnated or embedded and won’t wipe off, or they may cause scratches that require re-polishing.

In this situation, FOC offers a product called AnstromBrush™. Unlike the wipes, this product contains an abrasive to re-treat the end face. It is the same SiO2 abrasive used in the “final polish” disks. In this case, the abrasive is in a flocked pile, supplied as a five-inch disk that can be laid flat on a surface. It can be used with a cleaning solvent.

9. Factory-assembly processes must incorporate multiple clean-and-inspect steps

Assembly company production managers must allow for at least three and usually four cleaning steps in the assembly process. The final inspection, before the assembly “goes in the bag,” may be part of the documentation process.

10. Use what's most effective for you

Use the product(s) that are easiest, most consistent and reliable, and most cost-effective for your company’s situation. The goal is the process that gets the best results the first time. This may vary among sites, among companies, and among technicians.

Some companies may find that a lint-free-wipe-plus-fluid process may be cheapest per ferrule in cost of materials, but that it’s an art. That is, it requires training and skill to clean ends quickly and to get consistently good results. Other companies may prefer the cartridges or pen types because they prevent re-use of the same material on a second end face, even if it means a higher cost per end. And often, such advanceable-ribbon devices are preferred for field applications.

Additional Cleaning Considerations for MT and Cylindrical Ferrules

All the above cleaning tips apply to both MT-type ferrules and cylindrical ferrules. MT types have male ends with protruding pins, so there are additional requirements to avoid the pins when wiping. The female MT ferrules are easier to clean in this fashion. But the various cartridge and pen-type cleaning products have special tips or surfaces for MT ferrules.

There are, however, some additional problems that can contribute to losses in MPO connector joints, problems not associated with fiber-end contaminants. These problems that will be covered in a future article in this series.

Importance of Fiber End-Face Inspection

In the preceding tips, we frequently cited the importance of inspection, but we did not give many details on the inspection process. Such processes rely on microscopes and other optical inspection devices.

There are a range of products on the market. Some are handheld, and some are larger benchtop units for the factory. They offer different capabilities for inspecting end faces, measuring contaminants, documenting the results, and recording the images.

These inspection products will also be covered in a future article in this series.

[i]1 “The Impact of Optical Connector End Face Contamination and How to Prevent It; “February 5, 2010; First edition; NTT Advanced Technology Corporation. Another frequently cited study from NTT AT reported the responses of network owners and installers when asked about the causes of network failures associated with connectivity. According to NTT AT, 98% of installers and 80% of network owners said contamination was the primary cause of failures. Other causes included ferrule or connector damage, poor splicing, and excessive cable (fiber) bending.

[ii] 2. Connector assemblies typically are supplied with end caps, but the use of end caps is no guarantee that the end face is free from contaminants. In fact, the end caps themselves sometimes can be a source of small particles or contaminants. The end caps mainly are intended to prevent scratching during transportation. The packaging of assemblies with end caps does not mean that the connector is perfectly clean and ready to be mated to another.

This article is an original publication of Fiber Optic Center, Inc. It is shared publicly for educational and reference purposes to support learning and professional development within the fiber optics industry.

You are welcome to read, cite, or reference this material for non-commercial and educational purposes, as long as full credit is given to Fiber Optic Center, Inc. and the author.

Reuse, reproduction, or adaptation of this content — including rewriting, republishing, or incorporating it into new materials (such as websites, blogs, marketing text, technical guides, or AI-generated content) — is not permitted without prior written consent from Fiber Optic Center, Inc.

This material is protected by copyright law upon publication, even if not formally registered.

Use of this content for AI training, automated data extraction, or derivative content generation is prohibited.

Fiber Optic Center monitors and enforces the integrity of its intellectual property through digital identifiers and content tracking.

For more details, please refer to the Fiber Optic Center Content Use and Copyright policy.