Is your company entering the fiber optic cable assembly business, and you’re “setting up shop”? In your research, you may be discovering that most equipment is not offered as a one-size-fits-all, universal solution.

In fact, a key piece of fiber optic test equipment – the passive component tester (PCT) – must be correctly configured by the seller to support your product requirements.

When I talk with companies entering this business and researching PCTs, I ask a lot of questions about the cable assembly or patch cord/jumper they intend to fabricate. Why? Having a clear understanding of the product helps us clarify your test equipment requirements – and ensures you get an accurate quote. But here’s the issue: You may be in embryonic stages of “setting up shop” and may not have all the answers. So where do you start?

Start here: Answer these 7 foundational questions. This will help prepare you to order a PCT with the right test set configuration for your fiber optic product.

Passive component testers are a combination of firmware and hardware that, as noted earlier, must be correctly configured for your specific product. Many PCTs offer the following features:

- Insertion Loss/Return Loss module, which contains light sources and a detector

- A switch module, from 4 to 48 (or more) channels

- A chassis to fit the above modules, either 3 or 8 slots

While the above features may appear straightforward, every test equipment seller worth his salt will ask a surprising number of questions regarding the product you plan to test. To get started, here are 7 basic questions you should be prepared to answer. Your answers will guide you to select a PCT with the correct test set configuration – one that is the most economical solution for your requirements.

Question 1: What type of fiber will you test: single-mode, multimode, or both?

While this seems like an obvious question, some people assume a passive component tester can test both single-mode and multimode fibers. However, different modules are required to test single-mode and multimode. Keep in mind, that no testing module is universal.

Question 2: What type of connectors do you have?

You’ll need to clarify the connector type for each fiber optic cable assembly to be tested to get the right launch cables and detector adapter. (Often, cable assemblies do not have the same connector on both ends.) For example, if your patch cord includes any of the following connector types on both ends, then you can measure either individual Insertion Loss or total link loss using the Viavi MAP-300 8-Slot Mainframe, MAP-300 3-Slot Mainframe or MAP-300 3-Slot Mainframe with Touchscreen.

- FC or FC/APC

- SC or FC/APC

- ST

- LC or LC/APC

- MTP (MPO) male one end, female the other

- In essence, any cable that can be looped back and connected end to end

Question 3: How many channels will you need?

Recently I visited a fiber optic cable assembly manufacturer in Mexico. This company is fabricating large, 144-fiber cable assemblies. It would be prohibitively expensive for them to use a passive component tester with 144 channels in order to test all fibers at the same time. Instead, they use a 24-channel switch and test in batches of 24 fibers. In this instance, the manufacturer does not need to measure all connectors at once. How many fibers will you need to measure simultaneously? When researching passive component testers, be sure to ask how many channels each device has.

Question 4: Is the ability to test Return Loss (RL) required?

Do your customer specifications require you to measure Return Loss? If so, the passive component tester you select must offer this capability. Many end customers require Return Loss to be tested. This is based on the idea that good and consistent RL values imply that the manufacturing process is precise and stable.

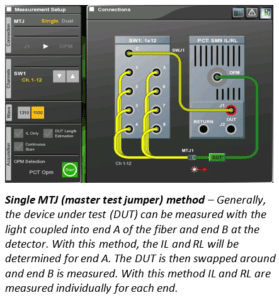

Question 5: Will you measure Insertion Loss (IL) individually per end – or measure total Insertion Loss?

Let’s say you’re fabricating a patch cord with a connector on both ends. Generally, the cable has zero loss over its short length. That means all the loss is associated with the connectors – the way they’re assembled, polished, and so forth. If you connect a patch cord into a circuit that’s already been referenced and you connect both ends of the patch cord, you will get the total loss for the patch cord. When both ends of the patch cord are connected, test equipment cannot discriminate which end the loss is coming from.

To measure individual Insertion Loss, you’ll need to purchase a PCT offering this capability. Measuring individual IL is beneficial because this can help to ensure your fiber optic cable assembly process is stable and consistent.

If the Insertion Loss at one end of the cable is high and the other end is low, this tells you there’s some variation in the process, and you’d want to look into that.

Question 6: Which measurement wavelengths do you require?

For the most part, corporate and government communication entities connecting data centers around the world – bringing fiber to the office (FTTO) and fiber to the home (FTTH) – have standardized measurement wavelengths. When researching passive component testers, clarify whether they support these wavelengths:

- Multimode: 850mm and 1300mm

- Standard module for single-mode: 1310mm and 1550mm

- The full wavelength version for single-mode adds: 1490mm and 1625mm for complete FTTX coverage

Question 7. What does the future hold?

I see a growing trend with manufacturers entering the fiber optic cable assembly market. Typically, their initial products are fairly simple. Soon, though, they make the jump from highly competitive, “commodity” products to more complex products with higher added value – and larger profit margins.

As you enter this market, you may only need relatively simple, entry-level test equipment. Based on my experience of working with a lot of companies entering the fiber optic market, it’s highly likely that you will expand to more complex products. These new products will require different test set configurations for your passive component tester. At this stage in your purchase process, take time to think about future product expansion. If possible, buy for the present – and for the future.

Concluding thoughts…

As you’re researching passive component testers to “set up shop,” I’m happy to offer guidance in your selection process. It’s critical that you purchase the RIGHT fiber optic test equipment. Your decision-making process should result in a PCT with the correct test set configuration that meets your current product requirements and, ideally, supports future expansion.

Additional resources from the FOC team include:

- View Test Technical Solution Content

- View the Glossary, Acronyms, Military Specifications for Connectors

- Q&A Resource: email technical questions to AskFOC@focenter.com

- Bookmark the Adhesive/Epoxy Page and Contact Info

This article is an original publication of Fiber Optic Center, Inc. It is shared publicly for educational and reference purposes to support learning and professional development within the fiber optics industry.

You are welcome to read, cite, or reference this material for non-commercial and educational purposes, as long as full credit is given to Fiber Optic Center, Inc. and the author.

Reuse, reproduction, or adaptation of this content — including rewriting, republishing, or incorporating it into new materials (such as websites, blogs, marketing text, technical guides, or AI-generated content) — is not permitted without prior written consent from Fiber Optic Center, Inc.

This material is protected by copyright law upon publication, even if not formally registered.

Use of this content for AI training, automated data extraction, or derivative content generation is prohibited.

Fiber Optic Center monitors and enforces the integrity of its intellectual property through digital identifiers and content tracking.

For more details, please refer to the Fiber Optic Center Content Use and Copyright policy.