Fiber Optic Center will be at OFC - Schedule your meeting with a member of the FOC team now

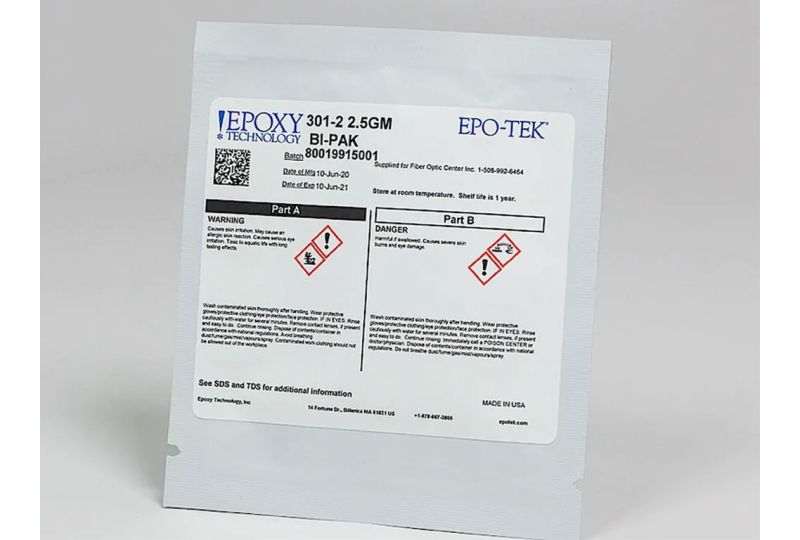

EPO-TEK® 301-2 Optically Transparent Epoxy, Heat Cure (2.5g)

ET301-2-2.5G

Features:

- Pot Life: 8 Hours

- Can resist yellowing over 17 days of continuous UV light exposure

- Resistant to impact and vibration

- Low-stress adhesive

- Passes NASA low outgassing standard ASTM E595 with proper cure

Applications:

- Semiconductor:

- Underfill for flip chips, glob-top encapsulation over wire bonds

- Spin coating at wafer level, including wafer-level packaging

- Fiber Optic Adhesive:

- Fiber bundling and ferrule termination

- Mounting optics inside fiber components

- Bonding glass coverslips over V-grooves

- Supports visible and IR spectral transmission

- Easy to use for potting, casting, encapsulation, and adhesive applications

- Excellent adhesion to glass, quartz, metals, wood, and most plastics

- Can be used for impregnating wooden or porous objects for artifact restoration

Physical Properties:

- Consistency: Pourable liquid

- Viscosity (23°C): 225 - 425 cPs

- Glass Transition Temperature, Tg: ≥ 80°C (degree Celsius); ≥ 185°F (degree Fahrenheit)

- Shore D Hardness: 80

- Coefficient of Thermal Expansion (CTE):

- Below Tg: 61 x 10-6 in/in°C

- Above Tg: 180 x 10-6 in/in°C

- Suggested Operating Temperature: < 300 °C (Intermittent); < 572°F

Optical Properties:

- Spectral Transmission:

- ≥ 94% @ 320 nm

- ≥ 99% @ 400-1,200 nm

- ≥ 98% @ 1,200-1,600 nm

- Refractive Index: 1.5318 @ 589 nm

Datasheet

SDS (Part A)

SDS (Part B)

Mixing Instructions

Fiber Optic Center

4.9 71 Google reviews

Represents overall Google Reviews of Fiber Optic Center, Inc.

Content Use Notice:

This product detail page and its content are the property of Fiber Optic Center, Inc. and are provided for informational and evaluation purposes.

You may view or reference this page for non-commercial use with proper attribution. Copying, rewriting, republishing, scraping, or using this content to produce new or modified content, including AI-generated content, is not permitted without written permission.

This content is protected by copyright law upon publication. Learn more