Fiber Optic Center will be at OFC - Schedule your meeting with a member of the FOC team now

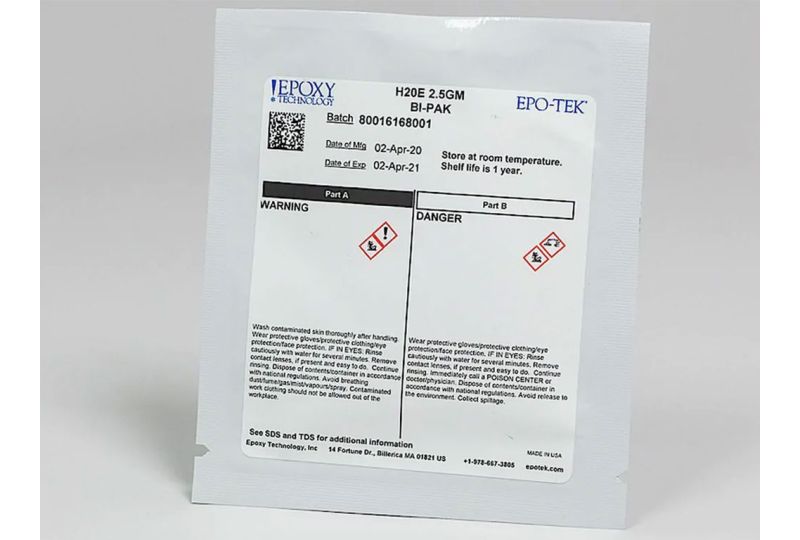

EPO-TEK® H20E Electrically Conductive Silver Epoxy, Heat Cure (2.5g)

ETH20E-2.5G

Extended Pot Life 2.5 days

**PMS fees included**

Features:

- Pot life: 2.5 days

- Silver-filled epoxy with a smooth, thixotropic consistency (Thixotropic 4.6)

- Die shear strength: > 10 kg

- NASA-approved, low outgassing epoxy (ASTM E595)

Applications:

- Semiconductor IC Packaging: Die attach, flip-chip applications, ultrafine-pitch SMD printing

- Hybrid Microelectronics: SMD attach adhesive, EMI/RF shielding for RF, microwave, and IR devices

- Solar-Photovoltaic: Solar cell stringing adhesive, chip attachment in solar concentrators

- Optoelectronics Packaging: Die bonding for laser diodes, fiber optic components, and LED chips

- Can be applied by many dispensing, stamping, and screen printing techniques

Physical Properties:

- Consistency: Smooth thixotropic paste

- Viscosity (23°C): 2,200 - 3,200 cPs

- Thixotropic Index: 4.6

- Glass Transition Temperature, Tg: ≥ 80°C (degree Celsius); ≥ 176°F (degree Fahrenheit)

- Shore D Hardness: 75

- Coefficient of Thermal Expansion (CTE):

- Below Tg: 31 x 10-6 in/in°C

- Above Tg: 158 x 10-6 in/in°C

- Suggested Operating Temperature: < 300°C (Intermittent); < 572°F

- Particle Size: ≤ 45 microns

Electrical and Thermal Properties:

- Thermal Conductivity: 2.5 W/mK based on the standard method: Laser Flash

- Thermal Conductivity: 29 W/mK based on Thermal Resistance Data: R = L x K-1 x A-1)

See datasheet for additional properties and application notes

Datasheet

SDS (Part A)

SDS (Part B)

Mixing Instructions

Fiber Optic Center

4.9 71 Google reviews

Represents overall Google Reviews of Fiber Optic Center, Inc.

Content Use Notice:

This product detail page and its content are the property of Fiber Optic Center, Inc. and are provided for informational and evaluation purposes.

You may view or reference this page for non-commercial use with proper attribution. Copying, rewriting, republishing, scraping, or using this content to produce new or modified content, including AI-generated content, is not permitted without written permission.

This content is protected by copyright law upon publication. Learn more