This blog is authored by the FOC TEAM including:

Marcel Buijs, EMEA Business Development, Technical Sales;

Erwin Gelderblom, EMEA Business Development, Technical Sales

Dan Rocheleau, Business Development, Technical Sales

In a perfect world, there would be ONE polishing procedure. In this ideal world, you could follow a standard “recipe” to implement your fiber optic polishing process – and following this recipe would make implementation quite fast and easy. Unfortunately, due to numerous factors influencing the polishing process, it’s impossible to offer a step-by-step “instruction sheet” that could accommodate everyone.

The good news is, there are some standard practices to follow. For example, it is standard to clean between each polishing step, and it is standard to meet certain geometry and visual appearance requirements. Also, while there may not be one polishing procedure specifically, there are a few basic ingredients to every recipe: time, pressure, and speed.

The exact recipe for your polishing procedure depends on certain factors in your fiber optic cable assembly process: your materials, equipment, methods, and environment. Also, it depends on your goals. What do you want to achieve in the polishing process? Which specifications do you need to meet?

The following paragraphs address some of the variables that affect the polishing process – and help to shed light on why a one-size-fits-all, universal polishing process does not exist.

MATERIALS: There is a wide variety of materials for ferrules and connectors, plus a variety of connector styles.

Here’s a key reason why we don’t have one standard polishing process: Singlefiber and multifiber ferrules are composed of different materials and have different shapes, diameters, hardness, and tolerances. Here are two quick examples:

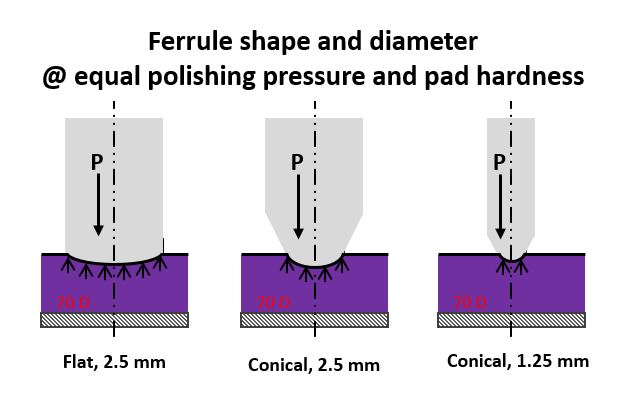

- Singlefiber ferrules are often pre-shaped with either a flat surface or a conical tip (with various conical angles like 45-60 degrees) and pre-domed, or even pre-angled and pre-domed.

- Zirconia ferrules are available in several diameters: 2.5mm, 1.58mm, 1.25mm, and 1.0mm.

Compounding this, there are many different connector components with considerations such as spring force and dimensional tolerances. For singlefiber connectors, the most common material is ceramic, yet some are stainless steel. Multifiber ferrules are made of a type of plastic (a glass-filled polymer).

EQUIPMENT: The type of polishing machine – as well as the condition of equipment and accessories – are key factors.

Generally speaking, when it comes to polishing machines, there are some commonalities. For example, every polishing machine needs to apply pressure to the ferrule for a certain amount of time. The polishing medium needs to be in motion to abrade the surface (to polish away material). All polishing machines work in a series of steps, starting with a rough grit of polishing film and moving to a finer grit.

The specific polishing machine you use will significantly impact the process. Why? Because various manufacturers employ different philosophies regarding how they approach polishing. Machines utilize different methods to apply pressure, different patterns of motion to use the complete area of the film, and different lengths of time:

- Pressure – Methods to apply pressure include pneumatic pistons, mechanical clamps, pulling, and pushing.

- The different motions of the abrasion film – Some polishing machines use a circular motion, some use a figure-8 motion, and most use a two-axis spinning-and-rotation motion (essentially, a continuous spiral moving over the surface).

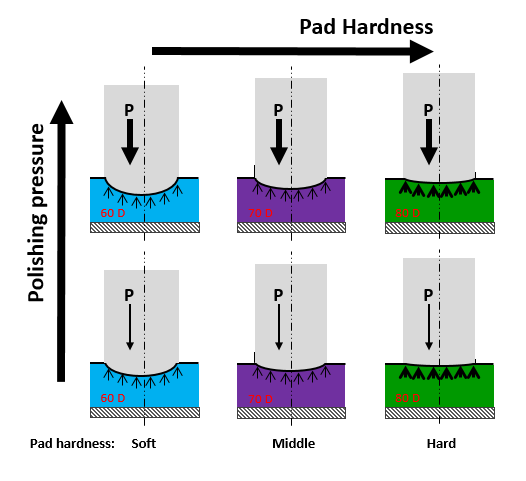

If you’re familiar with the polishing process, you know the lapping film is placed on a flat surface – usually a rubber pad or glass pad. The quality and condition of those pads are important. Also, it’s critical that ferrules properly align with the machine’s polishing surface; this ensures a consistent and equal amount of material is removed from each ferrule.

Any polishing machine worth it’s salt will have precise dimensional tolerances built in. But over time, there will be wear. This is one reason why it’s important to continually observe and monitor your polishing process.

Further, the recipe for your polishing process depends on your polishing film (aka lapping film). Different manufacturers have different types and qualities of film, offering various levels of durability and consistency. Every film cuts at a different rate. Clearly, all these different materials impact your polishing process.

METHODS: Product specification requirements dictate the polishing methods.

What are your requirements? Some applications require a PC finish, some require a flat finish, some require angled PC, and some require angled flat. Most fiber optic cable assemblies have very specific geometry requirements – yet some requirements are wide open. Some specifications allow scratches on the fiber’s core while some don’t allow any scratches on the core. Plus, there are different end face finish requirements that define how rough the surface can be. Some specifications require a very rough surface. For some, it doesn’t matter if the surface is rough. All these factors, taken together, will dictate the polishing methods needed to achieve your end goal and meet the requirements.

ENVIRONMENT: Temperature and cleanliness are often overlooked environmental factors that impact the polishing process.

If your polishing process uses rubber pads, it’s helpful to remember that pads age over time by UV exposure. Plus, they are sensitive to temperature changes. Ambient temperature will change the hardness of the rubber pads and, thus, change the results of your process. The aging process of rubber pads is not homogeneous and starts with hard spots in the rubber. As a result, the average ferrule Radius values remain acceptable, but the Apex values decline.

Cleanliness is another factor that impacts your polishing process. Keep in mind that all polishing processes are multistep. Between steps, you need to clean the polishing material away from the ferrules as you transition from a rougher-grit to a finer-grit polishing film. Plus, think about your environment. The polishing process creates contamination as you grind material from the ferrule. The level of cleanliness in your polishing environment will impact the amount of cleaning needed on the product and films between every step.

IN CONCLUSION

The above discussion is not meant to overly confuse or intimidate those looking to enter the fiber optic ferrule polishing world, but to explain the variables at play that will affect your polishing process – and to explain why a one-size-fits-all, universal polishing process does not exist. It is important for those who are considering entering the polishing world to understand that, in all cases, there WILL BE some level of process development investment needed to “dial-in” a process that meets your product and production needs.

If you’re implementing a polishing procedure, it’s helpful to know that Fiber Optic Center Polishing Instructions, which offer recommended polishing machine settings. These published machine settings are meant to serve as a general reference for a good starting point for your polishing process development. It is expected that minor changes to some recommended machine parameters will be needed in order to meet your specific product needs.

- Domaille 4 and 5 Series Polishing Instructions: https://focenter.com/polishing-instructions-for-single-fiber-and-mt-polishing-processes/

- Seikoh Giken SFP-550 Polishing Instructions: https://focenter.com/polishing-instructions-for-pre-domed-or-pre-angled-zirconia-ferrule-connectors/

- ÅngströmLap Lapping Film: https://focenter.com/angstromlap/

Fiber Optic Center has always worked together with the customer to make sure their manufacturing procedures produce the highest quality jumpers at the most effective cost basis. Over the next few months, we’ll be adding to this long available benefit by introducing new tiers of service.

This will include:

- On-site polishing process development (tighter control on geometry, reducing film cost and increase capacity).

- Purchase discounts on equipment purchase to be applied on lapping film and epoxy

- Preventive maintenance, calibration and verification of purchased equipment

- On-site repair or priority on available loaner equipment to ensure production continuation.

- Final inspection on produced cable assemblies (containing overall appearance, connector geometrical, optical and visual inspection connector as well as cross-sectioning.)

Please contact us for additional information. Phone numbers are: 800-473-4237 or 508-992-6464 and email is: sales@focenter.com.

Additional resources from the FOC team include:

- View Polishing Technical Solution Content

- View the Glossary, Acronyms, Military Specifications for Connectors

- Q&A Resource: email technical questions to AskFOC@focenter.com