This article continues FOC’s latest series on optical fiber manufacturing processes, providing an overview of coatings for a wide range of standard communication and specialty optical fibers. The main job of coatings is to protect the glass fiber, but there are many intricacies to this objective. Coating materials are carefully formulated and tested to optimize this protective role as well as the glass fiber performance.

Coating function

For a standard-size fiber with a 125-µm cladding diameter and a 250-µm coating diameter, 75% of the fiber’s three-dimensional volume is the polymer coating. The core and cladding glass account for the remaining 25% of the coated fiber’s total volume. Coatings play a key role in helping the fiber meet environmental and mechanical specifications as well as some optical performance requirements.

If a fiber were to be drawn and not coated, the outer surface of the glass cladding would be exposed to air, moisture, other chemical contaminants, nicks, bumps, abrasions, microscopic bends, and other hazards. These phenomena can cause flaws in the glass surface. Initially, such defects may be small, even microscopic, but with time, applied stress, and exposure to water, they can become larger cracks and eventually lead to failure.

That is, even with state-of-the-art manufacturing processes and top-quality materials, it is not possible to produce a fiber with absolutely no flaws. Fiber manufacturers go to great lengths to process preforms and control draw conditions to minimize the flaw sizes and their distribution. That said, there will always be some microscopic flaws, such as nanometer-scale cracks. The coating’s job is to preserve the “as drawn” glass surface and protect it from extrinsic factors which could damage the glass surface such as handling, abrasion etc.

Hence, all fiber receives a protective coating when it is drawn. Uncoated fiber occurs for only a short span on the draw tower, between the time the fiber exits the bottom of the preform oven and enters the first coating cup on the draw tower. This uncoated interval is just long enough for the fiber to cool so that the coating can be applied.

Coating dimensions

As noted above, most standard communication fibers have a 125-µm cladding diameter and a UV-cured acrylate polymer coating that increases the outside diameter to 250 µm. In most cases, the acrylic coating is a two-layer coating “system” with a softer inner layer called the primary coating and a harder outer layer called the secondary coating1. Recently, some companies have developed communication fibers with 200-µm or even 180-µm coated diameters for dense high-count cables. This development means thinner coatings, but it also means the coating must have different bend and mechanical characteristics.

Specialty fibers, on the other hand, have many more variants in terms of fiber size, coating diameter, and coating materials, depending on the type of specialty fiber and its application. The glass-cladding diameter of specialty fibers can range from less than 50 µm to more than 1,000 µm (1 mm). The amount of coating on these fibers also shows a wide range, depending on the fiber application and the coating material. Some coatings may be as thin as 10 µm, and others are several hundred microns thick.

Some specialty fibers use the same acrylate coatings as communication fibers. Others use different coating materials for requirements in sensing, harsh environments, or serving as a secondary cladding. Examples of non-acrylate specialty fiber coating materials include carbon, metals, nitrides, polyimides and other polymers, sapphire, silicone, and complex compositions with polymers, dyes, fluorescent materials, sensing reagents, or nanomaterials. Some of these materials, such as carbon and metal, can be applied in thin layers and supplemented with other polymer coatings.

With communication fibers currently being produced at levels near 500 million fiber-km per year, the UV-cured acrylates represent the vast majority (probably more than 99%) of all coatings applied to optical fiber. Within the family of acrylate coatings, the main vendors offer multiple variants for different draw-tower curing systems, environmental requirements, and optical and mechanical performance properties, such as fiber bending specifications.

Key properties of optical fiber coatings

Important parameters of coatings include the following:

- Modulus is also called "Young's Modulus," or "modulus of elasticity," or sometimes just "E." This is a measure of hardness, typically reported in MPa. For primary coatings, the modulus can be in single digits. For secondary coatings, it can be greater than 700 MPa.

- Index of refraction is the speed at which light passes through the material, expressed as a ratio to the speed of light in a vacuum. The refractive index of widely used telecom-fiber coatings from major suppliers such as Covestro ranges from 1.47 to 1.55. Covestro and other companies also offer lower index coatings, which are often used with specialty fibers. Refractive index can vary with temperature and wavelength, so coating indexes typically are reported at a specific temperature, such as 23°C.

- Temperature range typically extends from -20°C to + 130°C for many of the widely used UV-cured acrylates used with telecom fibers. Higher ranges are available for harsh environments. Ranges extending above +200°C are available with other coating materials, such as polyimide or metal.

- Viscosity and cure speed concern coating characteristics when being applied on the draw tower. These properties also are temperature dependent. It is important for the draw engineer to control the coating parameters, which includes control of the coating temperature.

- Adhesion and resistance to delamination are important characteristics to assure that the primary coating does not separate from the glass cladding and that the secondary coating does not separate from the primary coating. A standardized test procedure, TIA FOTP-178 “Coating Strip Force Measurement” is used to measure the resistance to delamination.

- Stripability is essentially the opposite of resistance to delamination – you do not want the coating to come off while the fiber is in use, but you do want to be able to remove short lengths of it for procedures such as splicing, mounting connectors, and making fused couplers. In these cases, the technician strips off a controlled length with special tools.

- Microbending performance is a case where the coating is critical in helping the glass fiber maintain its optical properties, specifically its attenuation and polarization performance. Microbends differ from macrobends, which are visible with the naked eye and have bend radii measured in millimeters. Microbends have bend radii on the order of hundreds of micrometers or less. These bends can occur during manufacturing operations, such as cabling, or when the fiber contacts a surface with microscopic irregularities. To minimize microbending problems, coating manufacturers have developed systems incorporating a low-modulus primary coating and a high-modulus secondary coating. There also are standardized tests for microbending, such as TIA FOTP-68 “Optical Fiber Microbend Test Procedure.””

- Abrasion resistance is critical for some specialty fiber applications, whereas most communication fiber gets additional protection from buffer tubes and other cable elements. Technical articles describe different tests for puncture and abrasion resistance. For applications where this is a critical parameter, the fiber or coating manufacturers can provide details on test methods.

Tensile strength

The key strength parameter of fiber is tensile strength – its resistance to breaking when being pulled. The parameter is expressed in pascals (MPa or GPa), pounds per square inch (kpsi), or Newtons per square meter (N/m2). All fiber is proof tested to assure it meets a minimum tensile strength. After being drawn and coated, the fiber is run through a proof-testing machine that puts a pre-set fixed tensile load on the fiber. The amount of load is determined by the fiber specifications or, especially in the case of most communication fibers, by international standards.

During proof testing, the fiber may break at a point with a weak area, due to some flaw in the glass. In this case, the fiber that ran through the testing gear prior to the break has passed the proof test. It has the minimum tensile strength. Fiber after the break also is passed through the machine and screened in the same fashion. One problem is that such breaks can affect the continuous length of fiber drawn. This can be a problem for some specialty fiber applications, such as gyroscopes with polarization-maintaining fiber, where splices are not acceptable. Breaks also can lower the fiber manufacturer’s yield. And an excessive number of breaks can indicate other problems in the preform and draw processes2.

How do coatings affect tensile strength? Typical coatings cannot increase a fiber’s strength. If a flaw is large enough to cause a break during proof testing, the coating cannot prevent the break. But as noted previously, the glass has unavoidable flaws that are small enough to allow the fiber to pass the proof test. This is where coatings have a role – helping the fiber maintain this minimum strength over its lifetime. Coatings do this by protecting minor flaws from extrinsic factors and other hazards, preventing the flaws from becoming large enough to cause fiber breaks.

There are tests to characterize how a coated fiber will withstand changes in tensile loading. Data from such tests can be used to model lifetime performance. One standardized test is TIA-455 “FOTP-28 Measuring Dynamic Strength and Fatigue Parameters of Optical Fibers by Tension.” The standard’s description says, “This method tests the fatigue behavior of fibers by varying the strain rate.”

FOTP 28 and other dynamic tensile tests are destructive. This means the fiber segments used for the tests cannot be used for anything else. So such tests cannot be used to characterize fiber from every preform. Rather, these tests are used to collect data for specific fiber types in specific environments. The test results are considered applicable for all fibers of a specific type, as long as the same materials and processes are used in their fabrication.

One parameter derived from dynamic tensile strength test data is called the “stress corrosion parameter” or the “n-value.” It is calculated from measurements of the applied stress and the time to failure. The n-value is used in modeling to predict how long it will take a fiber to fail when it is under stress in certain environments. The testing is done on coated fibers, so the n-values will vary with different coatings. The coatings themselves do not have an n-value, but data on n-values for fibers with specific coatings can be collected and reported by coating suppliers.

Coating characteristics and specialty fibers

What is the most important parameter in selecting coating materials? The answer depends on what kind of fiber you are making and its application. Telecom fiber manufacturers use a two-layer system optimized for high-speed draw, high strength, and superior microbending performance. On the other hand, telecom fibers do not require a low index of refraction.

For specialty fibers, the coating specifications vary greatly with the type of fiber and the application. In some cases, strength and mechanical performance—high modulus and high n-value – are more important than index of refraction. For other specialty fibers, index of refraction may be most important. Below are some comments on coating considerations for selected examples of specialty fibers.

Rare-earth-doped fiber for fiber lasers

In some fiber lasers, the primary coating serves as a secondary cladding. The goal is to maximize the amount of optical pump power coupled into fiber. For fiber lasers, pump power launched into the cladding helps stimulate the gain region in the fiber’s doped core. The low index coating gives the fiber a higher numerical aperture (NA), which means the fiber can accept more of the pump power. These “double-clad” fibers (DCFs) often have a hexagonal or octagonal glass cladding, then a round low-index polymer secondary cladding. The glass cladding is shaped by grinding flat sides onto the preform, and then the low-index coating / secondary cladding is applied on the draw tower. Because this is a low-index coating, a harder outer coating also is necessary. The high-index outer coating helps the fiber to meet strength and bending requirements

Fibers for power delivery

In addition to rare-earth-doped fibers for lasers, there are other specialty fibers where a low-index coating can serve as a cladding layer and improve optical performance. Some medical and industrial laser systems, for example, use a large-core fiber to deliver the laser power, say for surgical procedures or material processing. As with doped fiber lasers, the low-index coating serves to increase the fiber’s NA, allowing the fiber to accept more power. Note, fiber delivery systems can be used with many types of lasers – not only doped fiber lasers.

Polarization-maintaining fibers. PM fibers represent a class with several fiber designs for multiple applications. Some PM fibers, for example, have rare-earth dopants for fiber lasers. These cases may use the low-index coating as a secondary cladding, as described above. Other PM fibers are intended to be wound into tight coils for gyroscopes, hydrophones, and other sensors. In these cases, the coatings may need to meet environmental requirements, such as low temperature ranges, as well as strength and microbending requirements associated with the winding process.

For some interferometric sensors such as gyroscopes, one goal is to minimize crosstalk – i.e., to minimize the amount of power coupled from one polarization mode to another. In a wound coil, a soft coating helps avoid crosstalk and microbend problems, so a low-modulus primary coating is specified. A harder secondary coating is specified to address mechanical risks associated with winding the fibers. For some sensors, the fibers must be tightly wrapped under high tension, so strength requirements can be critical in the secondary coating.

In another PM-fiber case, some gyros require small-diameter fibers so that more fiber can be wound into a compact “puck,” a cylindrical housing. In this case, gyro makers have specified fiber with an 80-µm outside (cladding) diameter and a coated diameter of 110 µm. To achieve this, a single coating is used – that is, just one layer. This coating therefore must balance the softness required to minimize cross talk against the hardness needed for protection.

Other considerations for PM fibers are that the fiber coils often are potted with epoxies or other materials in a sealed package. This can place additional requirements on the coatings in terms of temperature range and stability under contact with other chemicals.

Conclusion

The idea of a single "perfect" coating for any specific type of fiber is unlikely, if not impossible. In practice, the coating compositions represent compromises between various parameters, including index of refraction, modulus, temperature performance, and draw-tower requirements. To address the mix of requirements, coating manufacturers have ongoing R&D programs to improve the performance of their resins and achieve a better balance of multiple parameters.

A major thrust of coating-resin R&D in recent years has been curing speed, especially for high-draw-speed telecom fibers. The development of UV LEDs rather than microwave-driven UV lamps for curing has stimulated work on resins optimized for the LED wavelengths. This development offers fiber manufacturers promising benefits in terms of temperature control and energy savings. Other areas of R&D include coatings for new types of sensors and coatings for fibers used in harsher environments.

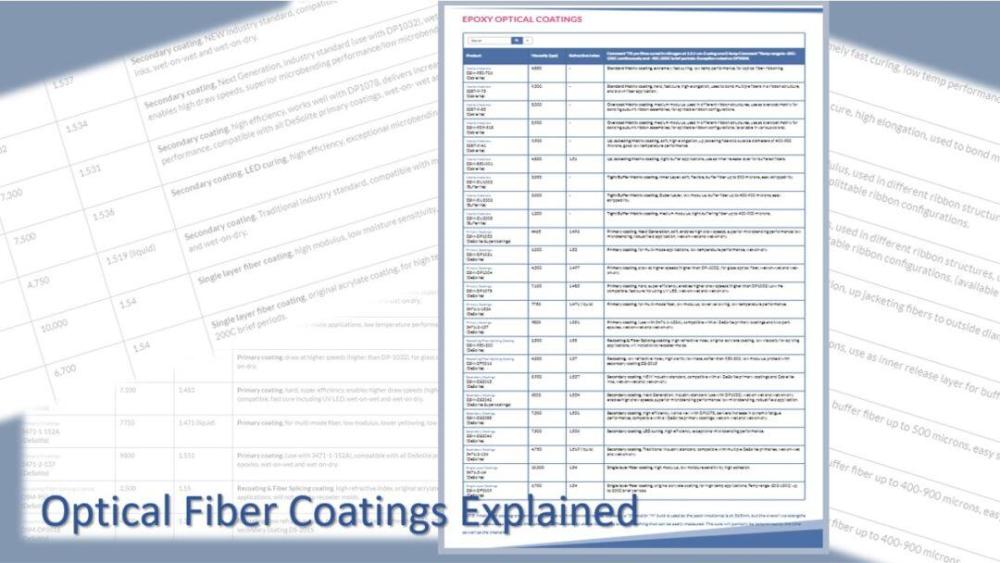

FOC's fiber consultants have extensive background in helping fiber makers address issues in specifying and applying coatings. Accompanying this article, FOC’s website has a list of coating resins we offer, shown in a table with their viscosity, refractive index, and a short description: FOC EPOXY OPTICAL COATING MATRIX. All are from Covestro’s range of coating products. The versions shown include offerings from Covestro for primary and secondary coatings, as well as resins for single coatings, specialty fiber coatings, and re-coating applications.

For more detailed questions about optical fiber coatings or procedures, please contact FOC’s technical consulting team at FiberOpticCenter@focenter.com.

1Most communication fibers have a very thin third layer to provide coloring. The fibers are color-coded so that technicians can identify individual fibers for splicing, connecting equipment, and other operations. This outer layer of colored material typically is only 2.5 µm thick. In such cases, the secondary coating extends the fiber’s outside diameter to 245 µm, and the colored layer extends it to 250 µm.

2In cases where the number of breaks is excessive, it is necessary to examine the size, distribution, and nature of the flaws. In such cases, the flaws can serve as indicators for diagnosing problems in preform processing, drawing, coating, or testing. FOC’s fiber specialists are available to assist with such investigations and modifications to preform and draw procedures.

This article is an original publication of Fiber Optic Center, Inc. It is shared publicly for educational and reference purposes to support learning and professional development within the fiber optics industry.

You are welcome to read, cite, or reference this material for non-commercial and educational purposes, as long as full credit is given to Fiber Optic Center, Inc. and the author.

Reuse, reproduction, or adaptation of this content — including rewriting, republishing, or incorporating it into new materials (such as websites, blogs, marketing text, technical guides, or AI-generated content) — is not permitted without prior written consent from Fiber Optic Center, Inc.

This material is protected by copyright law upon publication, even if not formally registered.

Use of this content for AI training, automated data extraction, or derivative content generation is prohibited.

Fiber Optic Center monitors and enforces the integrity of its intellectual property through digital identifiers and content tracking.

For more details, please refer to the Fiber Optic Center Content Use and Copyright policy.